CUSTOM WHEELSETS

FAT - MTB - GRAVEL

WORLD-CLASS OPTIONS

PREMIUM ALLOYS - POLYMERS - CARBONs

WHEELSETS

CRAFTSMANSHIP

All custom wheelsets are expertly hand-built in the USA or CANADA, and carry full factory warranties.

DURABILITY

All ATOMIK and DERBY custom wheelsets are 4-season AM/Trail rated (some are even DH rated!), designed to tackle adverse terrain and climate conditions.

CUSTOMIZATION

At RideFATbikes.ca, we offer full customization of our wheelsets, including :

COLOUR COMBINATIONS - custom Hub, Spoke, Nipple and Valve Stem colourways.

DESIGN SERVICE - custom frame, fork, and matching wheelset decals.

LASER ETCHING - exclusive hub design/logo laser etching available on all ONYX custom hub orders.

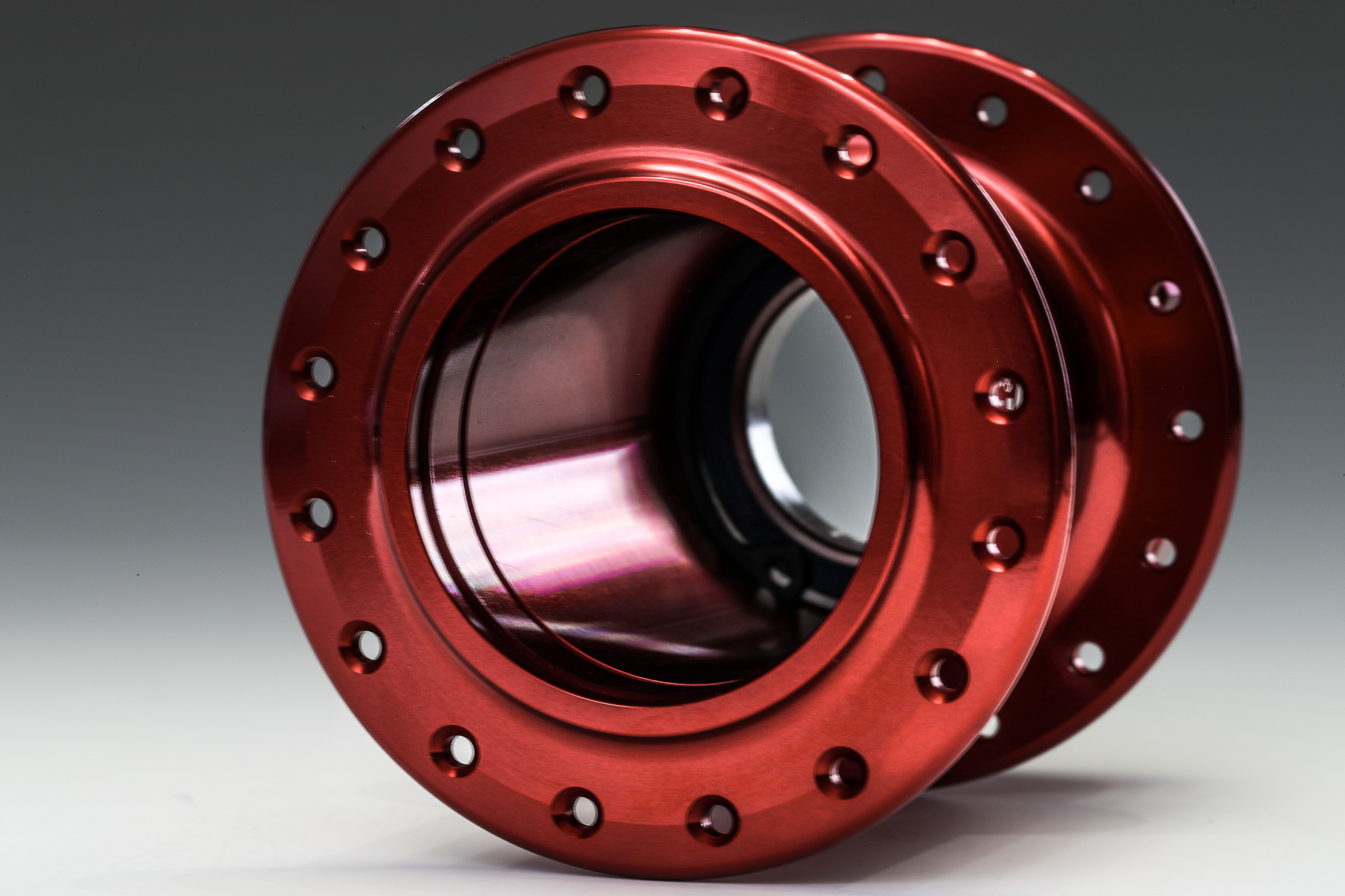

HUBS - from all the leading manufacturers : Industry Nine, Onyx, DT Swiss, Hope, Hadley.

RIMS - Various Rim Profiles and Widths (to reach target tire size/width combinations).

SPOKES - your choice of Sapim Race / CX-Ray alloy, to the extremely lightweight and strong BERD aerospace polymer spokes.

ATOMIK CARBON PHATTY / ONYX / BERD custom Fat bike wheelsets being prepared for RideFATbikes.ca customers!

WEIGHT

We offer many of the strongest, lightest and most durable FAT BIKE wheelsets in the Industry.

PRICE

We offer a premium custom build service with very competitive pricing, and match or beat all Manufacturer-authorized sales specials.

WARRANTY

All custom wheelsets have excellent warranties, and some even offer Lifetime Rim Strike protection.

FAT BIKE WHEELSET CHART

Price / Specifications / WEIGHT / Warranty

(very detailed chart created in DEC 2022) - Contact us for latest options

COPYRIGHT 2022 by RIDEFATBIKES.CA

FAT BIKE HUB CHART

Specifications / Weight / Features

COPYRIGHT 2022 BY RIDEFATBIKES.CA

(Charts best viewed with a widescreen device - click to <ZOOM> images)

PERFORMANCE

A well designed and built custom Fat Bike wheelset will increase performance, and save you time and watts with every crank of the pedals, for the lifetime of the wheelset!

If we were building a custom Fat Bike wheelset design, the Design Parameter order of preference would be :

HUB ENGAGEMENT RATIO

At the core of every custom wheelset, are the hubs. The ideal engagement ratio is as close to Zero as possible like the ONYX Classic or Vesper (0 degrees), or the Industry Nine Hydra (0.5 degrees) hubs. The worst “stock” engagement ratios on “premium” fat hubs are DT SWISS 18T ratchets (20 degrees) and HED or HOPE hubs at (8 degrees). (DT SWISS hubs can be upgraded with 6.7 degree / 54T ratchets).

ASTM CAT Strength Ratings

ASTM CAT 3/4/5 carbon rims are a “must have” for : 4-season, Trail / AM Suspension, 230-300 lbs rider+gear+bike total weight, or any significant jump/drops. (ATOMIK and DERBY rims are all CAT 3-4-5 rated). ASTM CAT3-5 wheelsets open many doors, and remove the limitations of “riding outside the wheelsets’ intended purpose” - see CAT2 below for some of the restrictions imposed on weaker rims).

ASTM CAT 2 - Sand and Snow only coverage. No jumps/drops. (sub 230 lbs total weight of rider+gear+bike). Not rated for suspension or 4-season trail/AM use. Often called “Winter Seasonal” Fat Bike wheelsets. (HED alloy or carbon rims fall into this category, along with the majority of Fat bike carbon rims on the market).

Many ASTM CAT 2 carbon rims have a minimum operational PSI rating, that will void the warranty if you ride below that PSI threshold (which can be 8 PSI or less). (Rim Strikes can cause catastrophic failures to these rims). Some CAT2 wheelsets, like the HED B.A.D. series, are engineered and tuned for winter performance riding on rigid hardtails - but are not designed for, nor covered under warranty, for riding outside their intended purpose (See notes above for CAT 3 riding conditions - we verified this with HED techs before disclosing the data here).

WARRANTY COVERAGE

Carbon Rims must have Rim Strike Protection and Lifetime Warranty if wheelset is to be used for aggressive or competition 4-season / all-weather / AM / Trail / Suspension use. Otherwise, the weaker rims will mostly likely fail, causing a lot of downtime - sometimes completely wiping out the winter riding season for unlucky riders waiting on replacement parts.

ATOMIK and DERBY both offer Rim Strike Protection and Lifetime Carbon rim warranties for ALL their rims, along with Crash Replacement Policies for those accident situations. 100% covered with these brands and they stand behind their products.

BERD SPOKE OPTION

BERD aerospace polymer spokes transform the ride quality. BERD are the best spokes on the market for high-end Fat bike builds. BERD spokes lighten full-fat wheelsets by 0.2-0.4 lbs (90-200gr) total weight, and add performance damping qualities to the ride. The BERD spokes absorb road and trail chatter, making you feel like you those Fat tires are riding on 1-2 less PSI of air. This allows you to increase the PSI by 1.0+ lbs and experience less rolling resistance, while having the same/similar damping qualities = more efficient ride. That translates to a more comfortable bike that uses less Watts to get from point A to B. Win-Win! There is no downside to using these spokes, aside from their initial installation cost.

ATOMIK CARBON rim purchases come with an option to build your next custom wheelset (Gravel / MTB / Road / FAT) with BERD aerospace polymer spokes.

Would you like to learn more about BERD spokes and our custom ATOMIK CARBON wheelsets? Click < Here >.

WEIGHT

Weight savings is where most customers gravitate to first, and often overlook warranty coverages, and hub engagement ratios.

When RideFATbikes.ca designs and builds custom wheelsets, weight is always a factor, but we are not going to cut corners to save a few grams, if it means reducing performance in any way.

Our goal is to have the best-performing Fat Bike wheelsets available in North America. Sometimes the custom wheelsets we sell may not be the lightest available, but they will always have the best warranties, engagement ratios, trail ratings, performance options, and replacement/repair polices.

SPECIAL FEATURES

100% SILENT RUNNING : Some products offer special features, that can add a lot of enjoyment to a bike ride. With regard to wheelsets, the ONYX Classic and Vesper hubs provide a 100% silent riding environment, bringing you as close to nature as possible, without any buzzing/whirling or motor sounds emanating from your bike. The trade-off is an increase in weight due to the Sprague Clutch and bearing design of the rear hub.

DAMPING : Two products in our custom Fat Bike wheelsets offer additional damping properties :

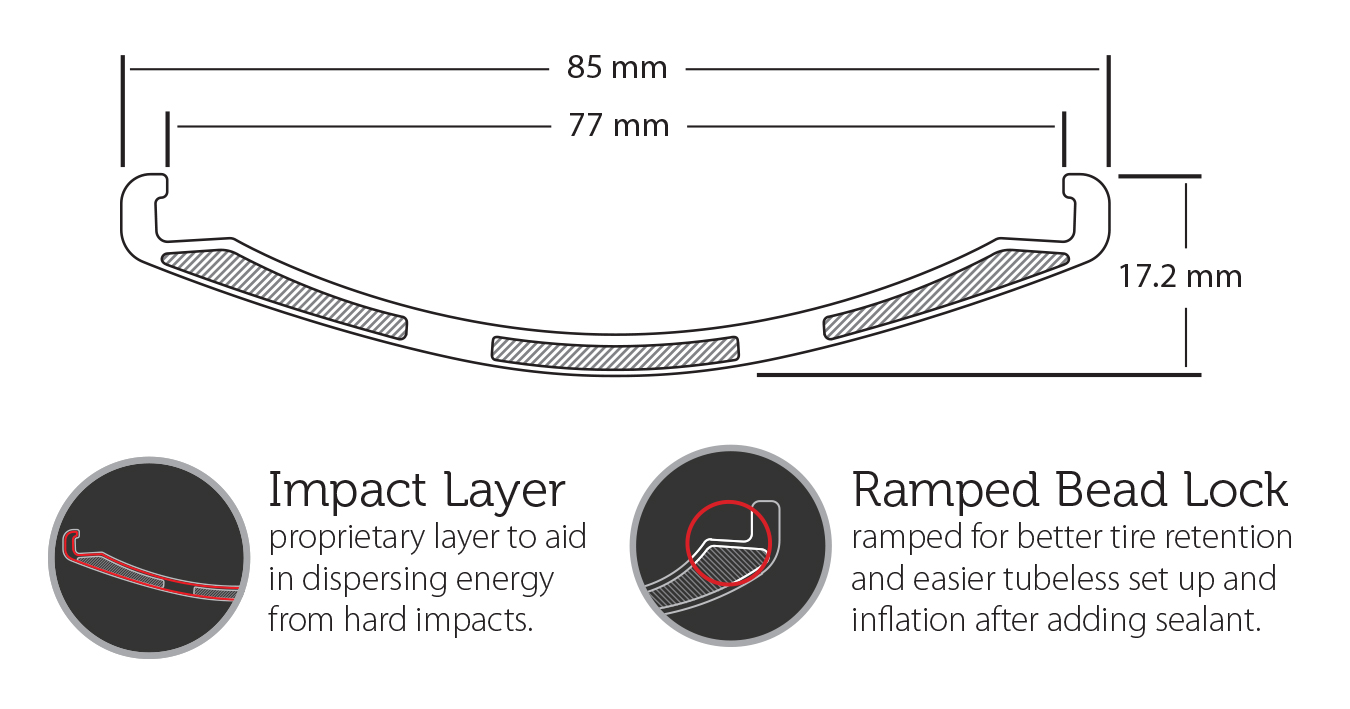

Atomik Phatty (FCT) Foam Core Rim : The Phatty 85mm features an aerospace foam core wrapped in a layer of composite material that is molded into the structure, creating a pseudo-semi wall rim that boasts increased impact strength, energy dissipation and stiffness, while adding additional damping characteristics.

BERD Spokes : Known as “the world’s lightest spokes,” Berd patented spokes are made from ultra-high molecular weight polyethylene, or UHMWPE—the same material found in bulletproof body armor. Not only does this advanced polymer have superior damping properties to minimize impact and vibration, it has 12 times the strength-to-weight ratio of the steel used in traditional spokes and a superior fatigue life.

ALLOY

FAT BIKE WHEELSETS

(up to 5.0” wide)

ATLAS 26” and 27.5” (80-82mm)

Our own RideFATbikes.ca design : custom alloy wheelsets using DT SWISS 350 Big Ride Hubs and the featherweight BERD aerospace polymer spokes weigh up to 10% LESS than most OEM carbon wheelsets out there, and cost significantly less too. 80-82mm external rim width accommodates 4.0” to 5.0” wide tires.

26” x 80mm Atlas/Berd wheelsets = 1980-2005g

27.5” x 80mm Atlas/Berd alloy wheelsets = 2135-2165g

MULEFUT v2 (80mm)

Stock Fat bikes will receive MULEFUT V2 SL80 alloy Fat bike wheelset by default, on any order, unless upgraded. 80mm external rim width accommodates 4.0” to 5.0” wide tires.

26” x 80mm MULEFUT v2 = 2600g

27.5” x 80mm MULEFUT v2 = 2740g

LITHIC (68mm)

Some OTSO VOYTEK fat bikes will receive LITHIC alloy wheelsets by default, depending on availability. 68mm external rim width accommodates 3.8” to 4.5” tires

26” x 68mm = 2525g

27.5” x 68mm = 2680g

ALLOY

(up to 2.8” wide)

ATOMIK ALLOY AL 345 TRAIL / AM (PLUS+) Wheelset

27.5” / 29” x 34.5mm

ATOMIK took what they learned designing some of the best carbon mountain bike wheels on the market, and set out to create a durable and affordable aluminum wheel without compromise. Enter, the Atomik AL345.

Designed to handle the abuse of modern trail and all-mountain riding, the AL345 is crafted from 6069 series aluminum for an optimal strength-to-weight ratio resulting in bombproof performance and reliability without the uphill penalty. Backed by a two-year limited warranty to the original owner, the AL345 is a feature-packed, performance driven, no compromises wheelset.

The AL345 features a low profile engineered to blend precise handling with a compliant ride. Both 27.5 and 29-inch versions feature a 34.5-millimeter outer diameter, and 30-millimeter inner diameter to provide an optimum profile and footprint on tires up to a 2.8-inch width.

The Atomik Carbon Upgrade Program – good for the life of the AL435 complete wheelset. If at any time the original owner chooses to upgrade to one of our carbon rim offerings, we will rebuild the wheel using your existing hubs—including new Sapim race spokes, brass nipples, all labor and return shipping—at no cost to the customer with the purchase of carbon rims.

Complete Fat Bike 150/177 or 150/197 TA wheelsets starting at: $925 USD + import costs (to Canada).

Approx. 1820g / 27.5” and 1850g /29” with DT SWISS 350 hubs.

Approx. 1.0 lbs lighter than the Fatback / Stans (PLUS+) wheelsets.

Choice of DT SWISS, INDUSTRY NINE, HOPE, ONYX Hubs.

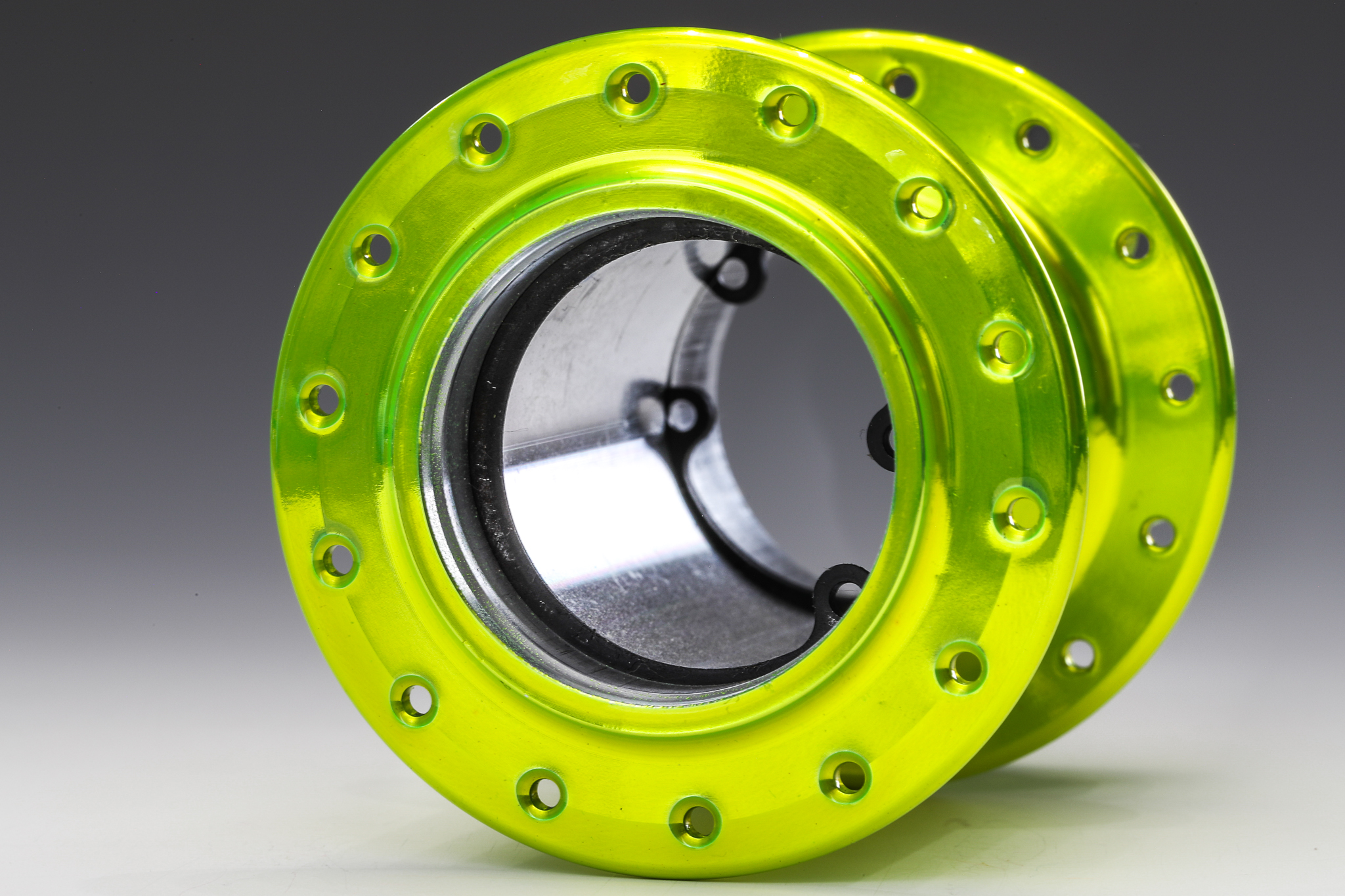

CARBON

FAT BIKE WHEELSETS

All of our Fat Bike custom CARBON wheelsets using ATOMIK or DERBY rims are :

INDUSTRY-LEADING 4-Season / suspension rated, specifically chosen for riding in all weather and trail conditions 24/7/365.

Backed by the best warranties in the business, using the latest construction techniques and materials.

ASTM CAT3 to CAT5 Ratings (this is very important w/ respect to product durability)

Note : All HED Fat bike wheelsets are only ASTM CAT2 rated :

HED Fat wheelsets are ideally suited for seasonal Sand and Snow use only. Lightweight wheelset design and construction - (rider weight + gear + bike) limit of under 230 lbs suggested. Groomed trail use during competition use suggested (especially if at higher speeds). HED declared minimum tire pressure required for warranty coverage was 8 PSI as of 2021 documentation, but they may have reduced that recently - best to contact them and ask for latest warranty coverage terms.

HED does not design or warranty their Fat Bike wheelsets for 4-season suspension use (we called their engineers and asked to make sure, before we printed that information on our website).

STRENGTH RATINGS :

ASTM CAT 2 (Sand, Snow, Gravel, Pavement) : All HED Fat bike rims fall under this category.

ASTM CAT 3 (Trail rated, all-terrain, 4-season, suspension rated) : ATOMIK PHATTY rims fall under this category.

ASTM CAT 4 (AM / All-Mountain Rated) : ATOMIK Chubby and FM Fusion Fiber rims fall under this category.

ASTM CAT 5 (DH / Downhill rated) : DERBY and ATOMIK CARBON “DH” rated rims fall under this category.

CARBON RIMS

PLUS+, MIN B-FAT and FULL-FAT

ATOMIK

DERBY

HED CYCLING

ASTM Rating : CAT 3 / 4

WARRANTY = Lifetime

4-SEASON USE : Yes

SUSPENSION USE : Yes

RIM STRIKE PROTECTION : Yes

CRASH REPLACEMENT : Yes

26” x 85mm (77i) AM 590g

27.5” x 43mm (36i) AM 470g

29” x 35mm (28i) AM 480g

ASTM RATING : CAT 4 / 5

WARRANTY = Lifetime

4-SEASON USE : Yes

SUSPENSION USE : Yes

RIM STRIKE PROTECTION : Yes

CRASH REPLACEMENT : Yes

27.5” x 45mm (40i) AM/DH 510g

27.5+” x 50mm (45i) AM/DH 530g

29” x 35mm (30i) AM/DH 485g

29” x 40mm (35i) AM/DH 495g

ASTM RATING : CAT 2

WARRANTY = 5 years

SEASONAL USE : Sand / Snow / Gravel

SUSPENSION USE : (voids warranty)

RIM STRIKE PROTECTION : No

CRASH REPLACEMENT : Yes

26” x 85mm (81i) XC 445g

27.5” x 85mm (81i) XC 465g

TIRE PRESSURE

Ride Responsibly!

Any cyclist can damage their carbon wheelset if they misuse the product, or ride at too low of a tire pressure, for the trail conditions, speed, and rider weight. “Rim Strike Protection” does not mean the carbon rims are invulnerable! Ride responsibly, and within the limits of the wheelset design, or you will be spending some downtime working on that warranty service claim.

TIRE (PSI) SETTINGS :

Common sense must be applied, when attempting to lower the tire pressure to under half the MAX PSI rating on the tire sidewalls, for any Fat bike tire. Lowering the tire pressure too much, will ultimately lead to both wheelset and tire sidewall damage. Rider+bike+gear combined weight, trail conditions, bike speed, suspension use, tire width/volume, and rim width, can all play critical roles in how a tire may perform, and also how well the wheel rim will be protected against impact damage.

Be very careful when riding under 5 PSI, especially on narrow, low-volume fat bike tires. Most fat bike tires perform well at between 8-12 PSI during 4-season use, with minor pressure decreases during winter riding.

DO NOT TRUST your bike pump to give accurate low pressure readings under 15psi (some floor pumps have shown to be off by as much as 3-5 PSI). Get a quality digital PSI tire gauge (like from SKS or Schwalbe) or an analog 0-15 PSI gauge like the Accu-gage by G.H. Meiser. Both style gauges can measure down to 0.25 PSI increments accurately, and you will be surprised how “dialed in” you can get your riding experience with minute adjustments in air pressure. 0.5 PSI can make a significant difference in handling during winter riding.

If you are using fat bike suspension, such as a Wren or Mastodon fork, make sure to increase tire pressure to 8-10 minimum PSI on the front tire, and usually at least 7-9 PSI on the rear tire, to match trail conditions.

If you are using low-volume tires, such as 26x4.0. 26x4.2, 27x4.0, and 27x4.2 tires, remember to increase tire pressure to higher values than you would normally use on 26x4.8” or 27.5x4.5” tires. Narrower tires, with less air volume MUST be set to a higher PSI, to protect the rims from impact damage and/or deformation, which can both lead to cracks and/or delamination of carbon rims - and dents or sudden tire pressure loss or tire blow-offs on several types of aluminum rims or single wall carbon rims.

If you plan on doing activities like jumps, drops, log rollovers, hopping over fallen logs, climbing or descending stairs, etc - you MUST increase tire pressure to a point that the rim is sufficiently protected from impact damage. In addition, the tire PSI must be able to support the rim from deformation upon impact or landing (may require 10-12 or more PSI). This usually will be at least 10 PSI on fat bike with tires at least 26x4.0” wide. 8 PSI may not be enough depending on your situation! “Misuse” of your wheelset will void the warranty.

Are lightweight “Snow-Only” (ASTM CAT2) wheelsets a bargain?

We do not think so. If you are going to pay about $2.1k-$2.4k CAD for an economy carbon fat bike wheelset, that has conditional use parameters placed on it, and a limited warranty that is good for 2 years (or less) - that amounts to an investment of about $1.1k/yr, before warranty voids in two years or less, on such products. Even when used under the best conditions, the manufacturer (of conditional use carbon wheelsets that are lower than ASTM CAT3 rated) clearly indicate that they do not expect the carbon to last more than the warranty period. This can indicate cheap carbon manufacturing techniques and layup, a high resin vs. carbon content, shortcuts that make the carbon more brittle, and more likely to deform, de-laminate, fatigue or crack within the warranty period.

Manufacturers in this category usually offer a very limited warranty that only covers “manufacturing defects” and NOT incidents incurred under normal usage, such as “wear and tear” events (aka - if the rim cracks or fails in any way during normal usage, the manufacturer is not going to cover the repairs/replacement). Instead, they proudly offer a “Crash Replacement” warranty. What does this amount to? Basically, your third rim is discounted 50%, and the customer covers all time/material and shipping costs/labour to get it replaced.

Any rim/wheel failure cuts your winter riding season short, dealing with returns and rebuilds. You can watch the blizzard outside, and wish you spent the extra$ on a better set of carbon wheels for your Fat Bike.

Crash Replacement Warranty - how much does it REALLY cost to replace that broken carbon rim?

What does “Crash Replacement Warranty (CRW) Policy” REALLY mean?

Well, if the manufacturer believed in their own carbon products and stood behind it under normal use, for 5years or more, you wouldn’t see them quickly offering a CRW, you would see them offering a LIFETIME warranty, or RIM STRIKE PROTECTION warranty.

When manufacturers do NOT believe in their product, and expect it to FAIL under normal riding during the stated warranty period, they will offer a CRW only. No money lost on their end if you crash out, or wear out their product, or it fails under normal use. Only you the consumer lose $$$ trying to replace a carbon rim that failed under normal operating conditions or “use within its intended operating parameters”. CRW’s work out well, when a freak incident occurs, like a dog biting into a carbon frame (had to deal with one of those!) or a carbon wheel cracking while riding on a soft sandy beach (had to deal with this one also - the company fought the claim (then fought multiple similar claims in a short timespan) - and they subsequently went out of business when customers sought legal action). So much for their Crash Replacement Policy!

Costs involved in a “Crash Replacement” warranty are :

(cost of the original wheelset +) cost of the new rim, which is usually discounted about 50% (most customers only think of the ne rim cost)

wheel disassembly costs (remove fat bike tire, tubeless tape, spokes, spoke nipples, valve stem, clean up sealant mess, clean hub and bearings)

shipping the new carbon rim from manufacturer to customer (add any customs/duty fees, taxes, and insurance to this cost)

purchasing new spokes, spoke nipples and tubeless conversion materials (new tape, valve stem seals, sealant)

new wheel assembly

tubeless tire installation fees

add taxes, shipping fees for new parts, and customs/duty fees on new parts

FACTOR IN LOGISTICS DELAYS OF 3-9 MONTHS for all new wheelbuilding parts needed. You are probably now well into 1.5x $$ the cost of that original “economical” wheelset.

is a “Crash Replacement” warranty really worth it? (No) . It only covers the second rim cost, and the customer covers all the other costs noted above.

ECONOMY SNOW-ONLY SEASONAL WHEELSETS

(OUR COMPETITORS SELL THEM, BUT WE DO NOT)

We have been down this road, and pulled them from our shelves.

RideFATbikes.ca does not sell seasonal “snow-only” (ASTM CAT2) rated FAT Bike wheelsets, because they can easily break, and the delays battling the manufacturer’s warranty claim process, can take longer than an entire winter riding season. “Snow-Only” conditional use Fat Bike wheelsets usually have additional riding limitations such as :

Low rider+bike+gear Max weight (under 230 lbs)

The construction process of saving weight on seasonal-use carbon rims, by hollowing out and thinning rim walls, comes at the expense of decreasing rim durability and longevity.

Requirement of at least 6-8 PSI tire pressure at all times

Thin carbon construction of rim bed and rim wall, increases chance of flex under load causing tire burbs or blowouts.

Conditional Limited Warranties, where ANY damage or perceived misuse (at manufacturer’s discretion) results in needing to reinvest in new rims + labour + shipping costs + delays.

Rim Strikes void the warranty

Seasonal-use carbon FAT rims are commonly built to only a 2.5mm bead wall thickness (4-season rims are typically 3.5-4mm). Saving 50g-100g per wheel on snow-only rims, comes with the usual penalty of them being completely useless after a rim strike.

Incompatible with suspension use - either front or rear suspension use can cause the rims to deform, fatigue or crack, especially if ridden while on dirt trails.

Expected lifespan of the carbon used in these rims can be 2 years or less, and is directly reflected in the limited warranty coverage.

HUBS

SPOKES

Aerospace Polymer

CX-Ray

Race

PRO-BUILD OPTIONS

FAT BIKES

ATOMIK CARBON PHATTY 85

150 / 197 TA 6-bolt

(Lifetime Warranty, includes Rim Strike protection)

Atomik Phatty 26” x 85mm carbon wheelset w/ Foamcore Technology, and BERD Polymer spoke :

DT Swiss Hubs / BERD SPOKES:

1870g (+/- 40g)

Onyx Hubs / BERD SPOKES:

2010g (+/- 40g)

Silent, 0-degree engagement, Ceramic bearings.

WHY PAY MORE FOR PREMIUM FAT BIKE CARBON WHEELSETS ?

Ride that carbon wheelset for the benefits you paid for : Strength, Lightweight, 4-season Trail rated durability, and peace of mind.

Atomik Carbon does a tremendous amount of testing on their wheelsets and firmly stand behind their products, with excellent warranties and crash replacement programs. They are arguably the lightest and strongest Fat Bike wheelsets on the market - designed for 24/7/365 use in grueling AM/Trail rated environments and under severe weather conditions below -30c. Lowering Fat tire pressure to 4 PSI for maximum winter traction during low-speed winter riding, is not a problem - but raise tire pressure accordingly (8+ PSI) to protect the rims from deformation or impact damage when riding aggressive singletrack or on suspension Fat bikes with 100-120mm travel. Suggestion of 10+ PSI on full-suspension fat bikes with 120-150mm travel and narrow (low-volume) 26x4.0” or 27.5x4.0” tires.

BERD SPOKES - A flexible polymer spoke able to absorb a large amount of vibration to smooth out the ride, while decreasing wheelset weight by about 200gr over conventional steel or alloy spokes.

ATOMIK PHATTY FOAM CORE - An aerospace-grade layer of foam is encased within the carbon dual-layer rim walls, to both strengthen the rim and absorb impact shock, while providing enhanced damping qualities. This AM/Trail-rated lightweight carbon rim is capable of surviving rim strikes without collapsing. Backed by a Lifetime manufacturing defects warranty, crash replacement program, and Rim Strike Protection.

EMAIL FOR LATEST PRICING ON PRODUCTS NOT LISTED

FAT BIKE HUBS

RideFATbikes.ca custom Fat Bike wheelsets

built with the following Hubs :

ONYX - DT SWISS - HADLEY - HOPE - INDUSTRY NINE

Consider the following Hub features when ordering your next custom wheelset :

EXTREME TEMPERATURE RATING - DRAG/RESISTANCE - PAWL ENGAGEMENT - BEARINGS - WEIGHT - WARRANTY - PRICE

RANKING HUB SPECIFICATIONS

Many people call or email to ask “What are the BEST Fat Bike hubs?” - There is not a simple answer to that question, unless you qualify it with specific features you are looking for, as each hub design has its merits. We took the time to put together a detailed chart that filters through all the marketing hype, and provides the essential facts. All data is from published material, or actual weights of parts on a Park Tools DS-2 Digital Scale.

Some manufacturers only posted the claimed weights for their 170 / 177 hubs (probably because they were lighter than the 190 / 197 variants). As a baseline, we weighed the 197x12mm TA 32H 6-bolt hub versions, w/ SRAM 12spd XD Driver installed.

What do we rank as most important?

Engagement Ratio

(this is by far the most important stat for a high-performance Fat Bike hub. Once you ride a zero-degree engagement hub, like an INDUSTRY NINE HYDRA or an ONYX CLASSIC or VESPER, you will not want to go back to high-engagement hubs)

Drag Resistance (bearing and seal quality)

Warranty (and customer support)

Weight

Noise Level

Cold-Weather rating

(CW rating ranked last, because it can be modified by servicing the bearings and repacking with low-temp grease)

Best Engagement Ratio

ONYX

INDUSTRY NINE

HADLEY and FATBACK

DT SWISS (54t ratchet)

HOPE

DT SWISS (18t or 36t ratchet)

LOWEST DRAG RESISTANCE

ONYX

DT SWISS (32t)

i9 HYDRA

FATBACK (2nd if at -25C)

HADLEY (tie for 4th)

HOPE (did not test)

WEIGHT

DT SWISS

INDUSTRY NINE HYDRA

HADLEY

FATBACK

HOPE

ONYX

NOISE LEVEL

ONYX (100% silent)

DT SWISS (quiet)

HADLEY

i9 HYDRA

HOPE

FATBACK AE (loudest)

Quick Ranking of Fat Bike Hubs : as you can see, there are a few hubs that rank near the top in all categories. DT SWISS, ONYX, i9 HYDRA.

DT SWISS 350 “Big Ride” : $ : A lightweight hub, that is easy to service, easy on the ears, and works well in winter. Drawback is the not-so-great engagement ratios, especially the stock 10 or 20 degree stock hubs used in many wheelset builds. UPGRADE those ratchets to 54t, or else you will always need to rotate the crank up to 20 degrees to get the freehub to engage.

I9 HYDRA : $$ : Made in USA (North Carolina) Performs well at everything, amazing engagement ratio, lot of anodized colours to choose from, lightweight, somewhat loud (ranks in the middle of the group), quieter than the TORCH series (previous version). Excellent customer support. ** Industry Nine restricts production on their Fat hub to one month a year, as of NOV 2022 (in 150/197 sizes only), and did not produce the Classic hub in 2021 and most of 2020.

ONYX CLASSIC FAT : $$ : Made in USA (Minnesota) Excellent customer support. (“Vesper” hub series for MTBers, “Classic” hub series for Fat bikers). This is our choice for the best production Fat Bike hub again for 2022 (i9 would either be a tie or a close second if they were in production year-round). ONYX has the most anodized and powder coated hub colour options for custom builds. ONYX IS SILENT and ENGAGES INSTANTLY - Huge selling point! In 2021/22, we found that ONYX hubs with the lack of pawls, and incorporating premium Hybrid Ceramic Enduro bearings were noticeably faster and had less Drag Rolling Resistance than any other hub tested. Upgrading to Enduro ZERO or XD-15 bearings takes these hubs to another level of performance.

FATBACK : $ Novatec confirmed the serial numbers inside the branded “197SL AE” hub body belong to the Novatec “B2” series of Fat bike hubs as of 2016+, and made in Taiwan/China. FATBACK had the loudest hubs in our test. Hadley (USA MFG) used to make Fatback’s hubs prior to about 2015, and those hubs had an “H” branded onto the hub body. Fatback took the technology gained from Hadley and later offshored the fabrication to China or Taiwan in about 2016, using the Novatec B2 series hub bodies, and repacking EZO bearings with low-temperature grease (SKF LGLT/2 or similar), according to Novatec and Fatback sources.

HADLEY : $$ Made in USA (California) Premium titanium hubs. Hadley hubs are used in several top-tier wheelsets by companies like Santa Cruz. Hadley does not have a company website (seriously!) but they do exist in southern California.

HOPE : $ : Made in the UK. Quality product. Liked by owners. A bit heavier than the other brands. Low scoring 8 degree engagement ratio. Price point is good for budget wheelsets.

RideFATbikes.ca FAT BIKE HUB (DRAG RESISTANCE) test results in SPRING 2021

RideFATbikes.ca decided to do our own real-world Fat Bike hub tests in 2021/22, to see how they compared with the University of Alaska closed-condition lab test completed in 2018.

In our tests, to baseline the equipment used in the test, we took the same/similar Fat Bike wheelsets, using the same bike, the same tires, inflated to the same PSI, but each wheelset was laced to 4 different hubs (stock grease, no hub or bearing modifications). We put the equipment through several test scenarios in above freezing temps, between 9C and 18C.

Note : the hubs selected were the newer 2020/21 versions of the top 4 hubs first used in the University of Alaska 2018 test.

FAT BIKE Hubs used in test (150/197 TA 6-bolt):

Hadley titanium

(w/4 pawls, 5 degree engagement ratio)

DT SWISS 350

(w/54T, 6.7 degree ratchet upgrade)

Onyx Classic

(w/ stock ceramic bearings and 0 degree Sprague clutch engagement)

Fatback Alaska Edition (AE) v3

(latest version, 6 pawls, 5 degree engagement)

(did not include HOPE hubs in test b/c they were not available at the supplier level in Canada in Spring 2021)

(did not include the “new” Industry Nine Hydra Fat Bike hubs, because they are temporarily discontinued by I9 in 2021 - we hope they bring them back into production soon!)

SUMMER GREASE USED IN TEST :

Muc-Off Bio-Grease (cherry colour), Team Sky Workshop edition, was used to lightly coat the front and rear axles in each test.

No modifications were made to the hubs, their bearings, or the factory grease used to pack the bearings.

Fat Bike, Tires and Wheelsets used in the test :

9:ZERO:7 LYNX Carbon, rigid carbon fork, w/SRAM AXS wireless drivetrain, and Atomik Phatty Carbon and our own Atlas/Berd alloy wheelsets (both sub-2000gr). (22+ lb fat bike). All wheelsets were laced with the above hubs, and brand new Schwalbe ADDIX Jumbo Jim 26” x 4.8” TLR tires (setup tubeless) were used at 12 PSI on all wheelsets. (yes, this PSI is a bit higher than normal for trail riding, but we needed to test rolling speed and efficiency, so higher than usual PSI was necessary for hardpack and pavement testing.)

Here are the SPRING/SUMMER results :

Fastest hub when coasting = ONYX “Classic” series w/ ceramic bearings (which come stock with these hubs)

The ONYX Classic hub definitely had the least amount of resistance when coasting, which makes sense because (1) it was the only hub that used premium ceramic bearings (stock), and (2) there is no constant Pawl or ratchet engagement to create extra Drag Resistance. The ONYX CLASSIC hub was at least 5% faster (or more efficient at speed) than the next best place finisher, and 10% faster than the last place Fatback AE v3 hub.

Example : In one test performed under identical conditions, on a downhill run (all-road), which begins at a rolling stop and descends 47m over 0.4km, the Onyx Classic hub hit 55kph while coasting (no pedaling from the initial rolling start), where the next best speed was 52kph (DT Swiss 350), 51kph (Hadley titanium) and 50kph (Fatback AE v3). The test was verified with a Garmin Satellite-based GPS (and not an onboard speed or cadence sensor on the bike)… and that Garmin GPS was verified accurate multiple times (for its own merit), while cycling past a neighbourhood Speed Radar trap sign that had a digital readout.

Fastest hub when pedaling = ONYX “Classic” series w/ ceramic bearings

The ONYX CLASSIC hubs were notably faster than all the other hubs while pedaling. This was especially evident one weekend in Toronto Ontario, when the downtown Lakeshore Road was closed off to vehicular traffic and only cyclists were allowed on the 3-lane road. We could sprint with our fat bikes for over 1km, and the ONYX CLASSIC hubs could obtain 45+ kph sprint speeds repeatedly, with the least perceived effort, using a standard 32T oval front chainring / 10T-52T rear cassette tooth gearing. (top speed was low 50+ kph for a few hundred meters, wearing baggy MTB clothes, backpack, standard MTB helmet, w/platform pedals (and doing a bit of strategic drafting!) - Who says fat bikes are slow ?! cheers!).

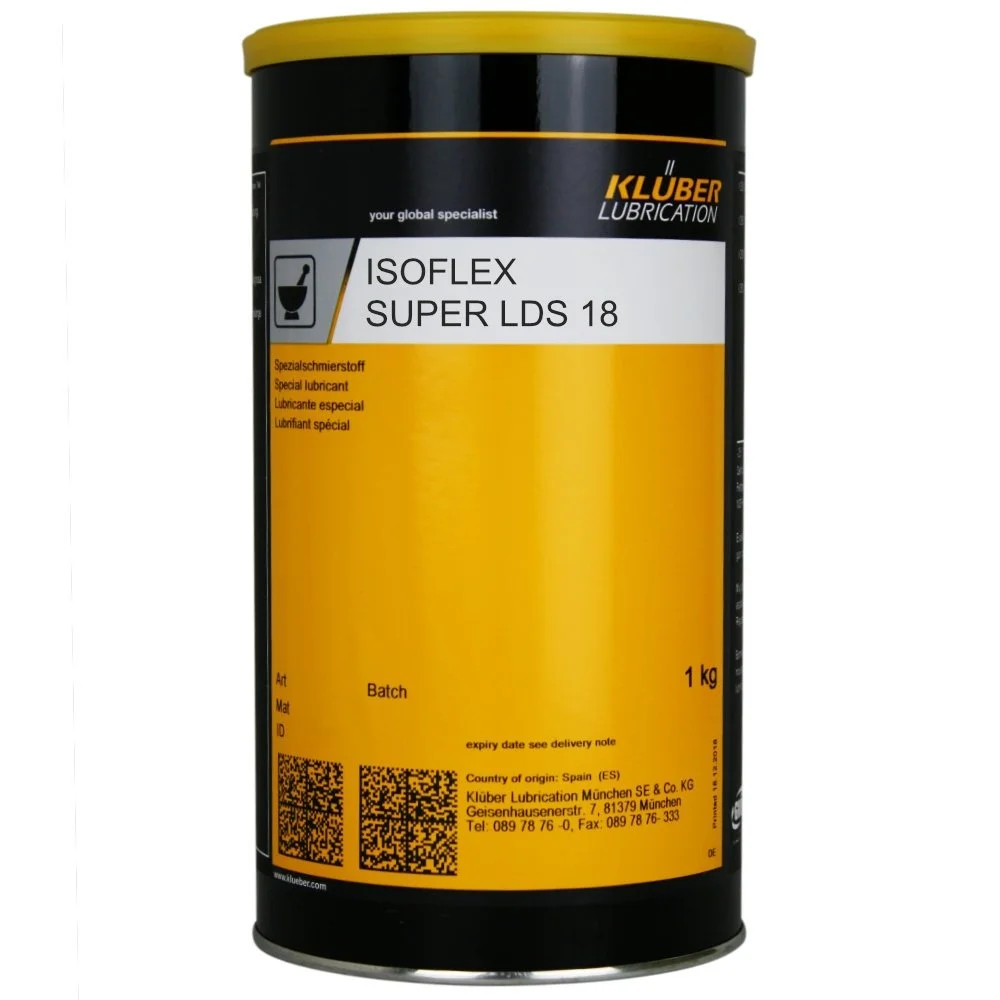

KLUBER ISOFLEX SUPER LDS 18 Grease - (click to ZOOM)

GREASES USED in the Winning Hubs :

Re-pack the bearings in any of these hubs with SKF LGLT/2 Low-Temp grease to get excellent extreme winter temp performance down to to -50C, since that was reportedly the same grease used in the Fatback AE hubs, in the 2018 tests done at the University of Alaska, that allowed that specific hub to place so well in those specific tests. This grease also has optimal performance right up to 100C, at very high rotational speeds, such as used in professional inline skates wheels, or electric motors in the medical and dental fields. (It is not inexpensive!, btw)

Another great alternative is to use KLUBER ISOFLEX SUPER LDS 18 grease, which works in temperature ranges from -50C to 120C, with an operational range of 300hrs inbetween cleaning/repacking. ONYX uses this grease for their premium ceramic bearing hub clutch mechanisms.

SKF LGLT/2 Low-Temp Grease - (Click to ZOOM)

HUB BRANDS

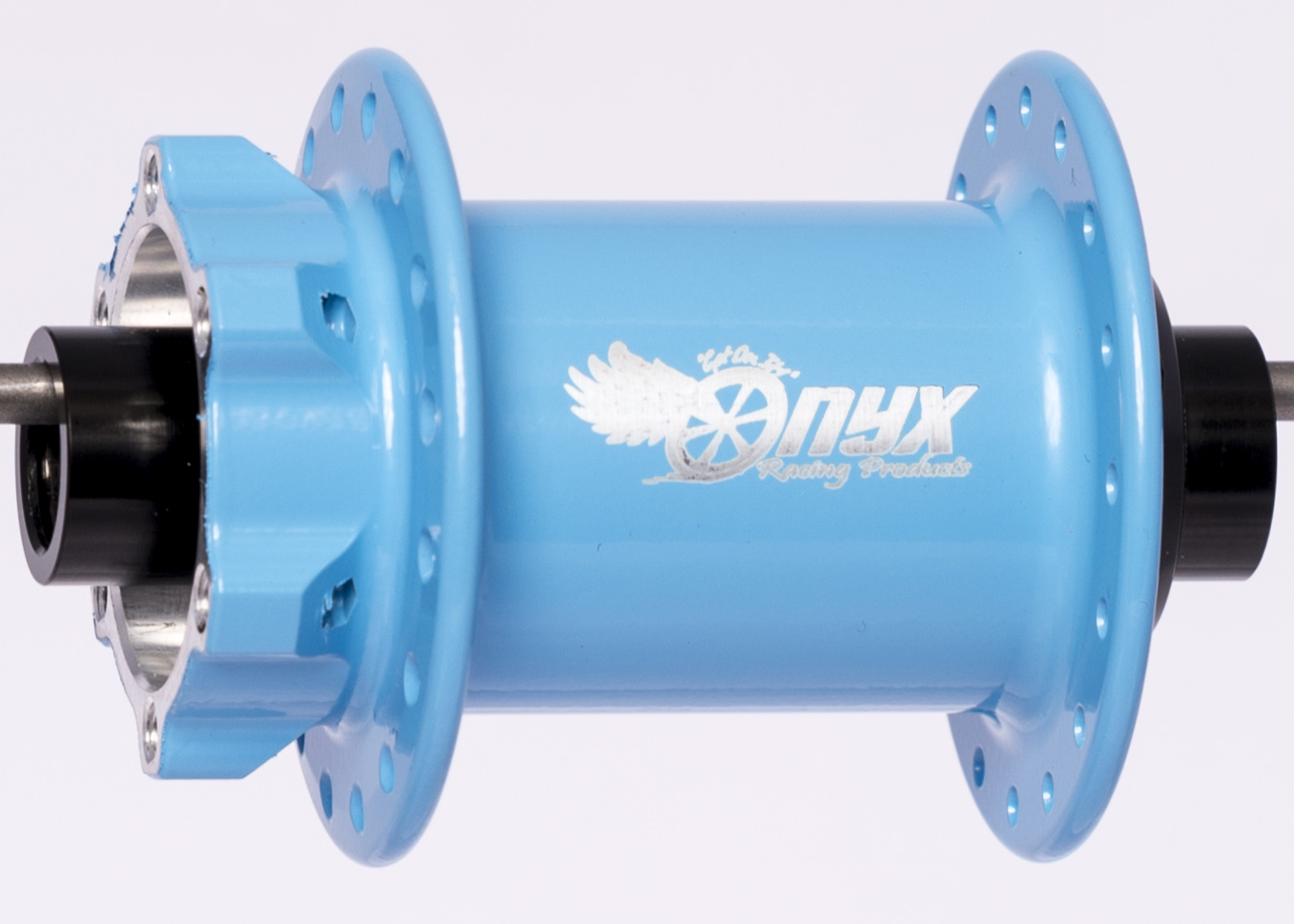

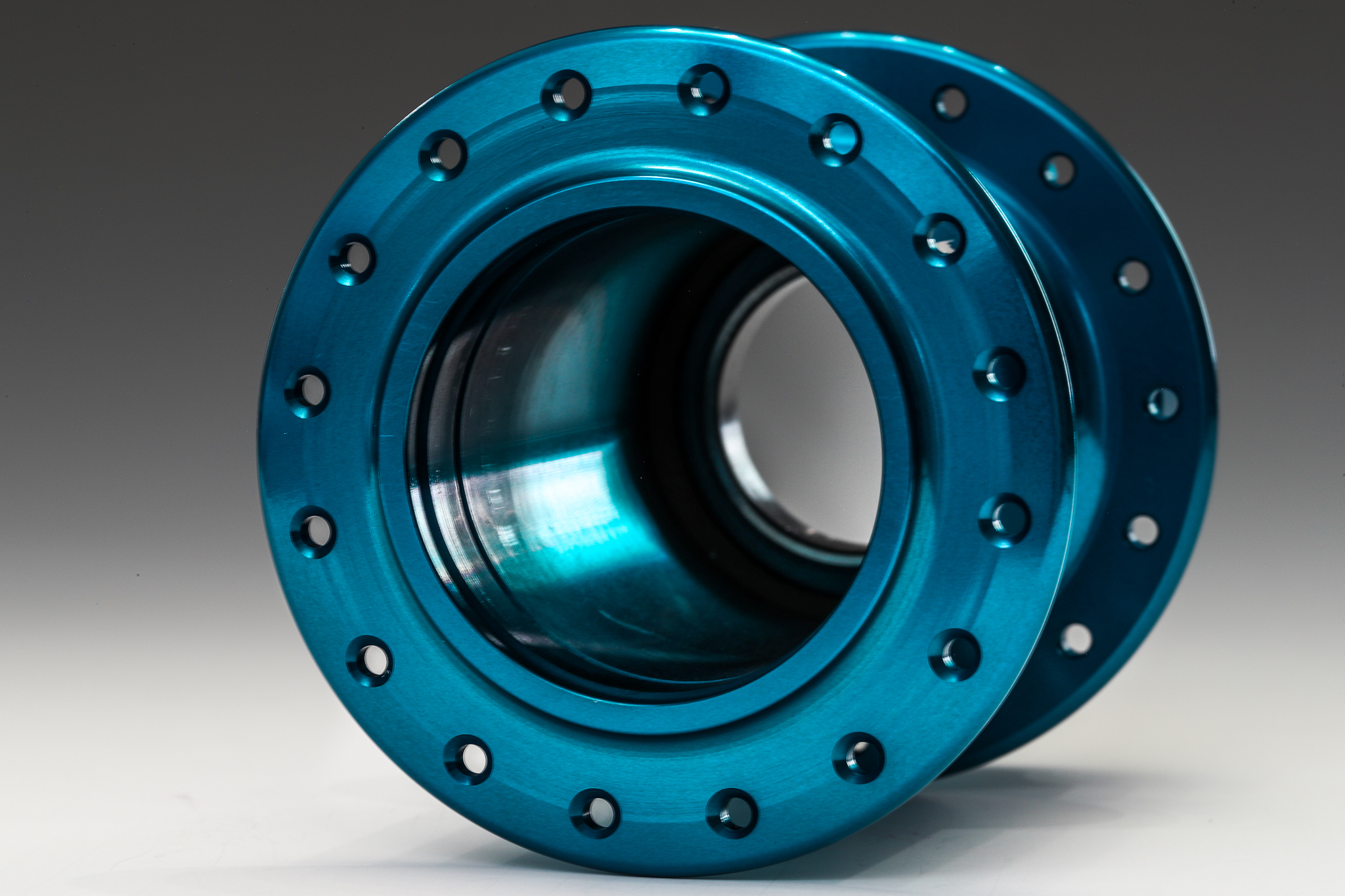

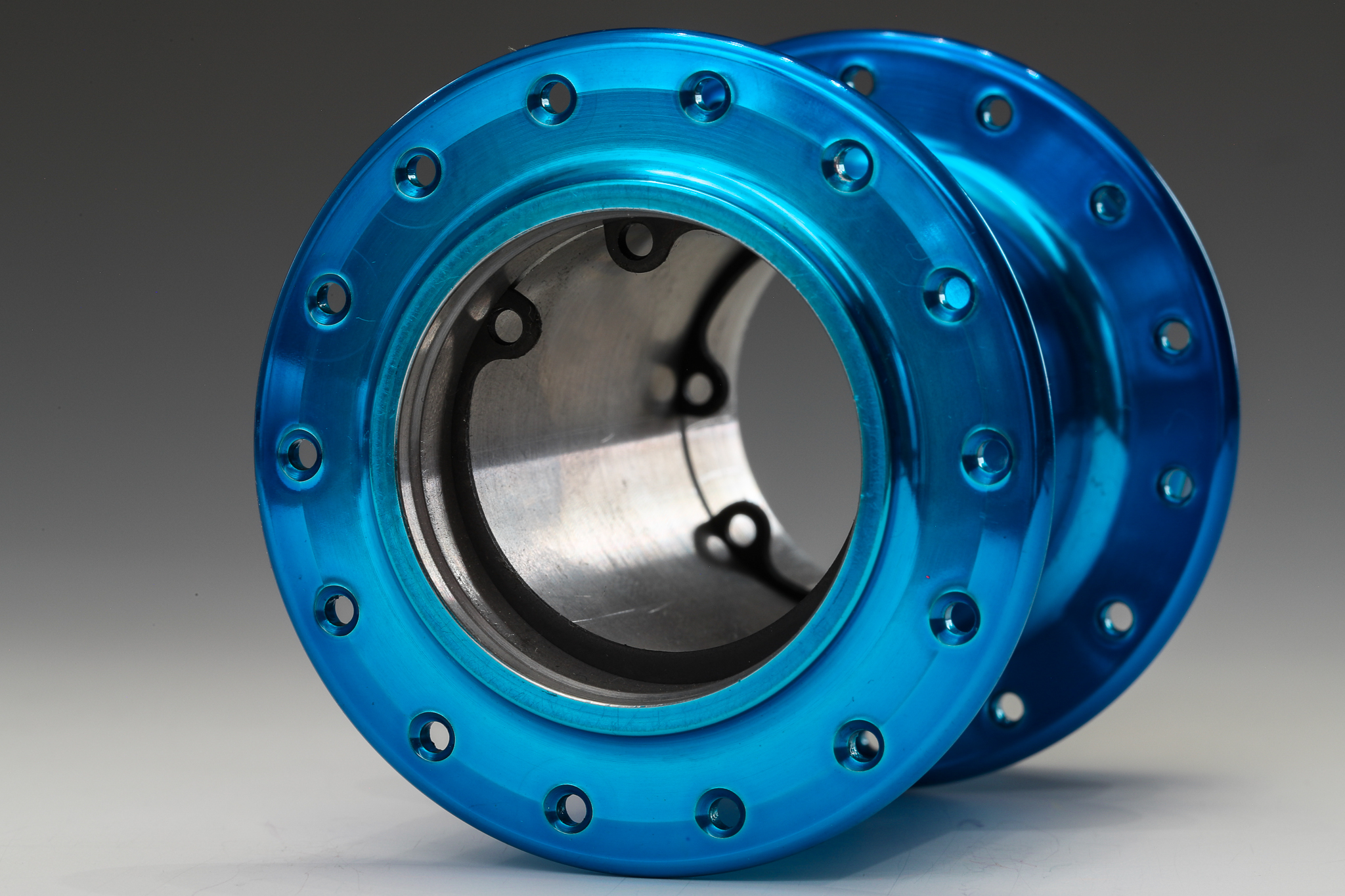

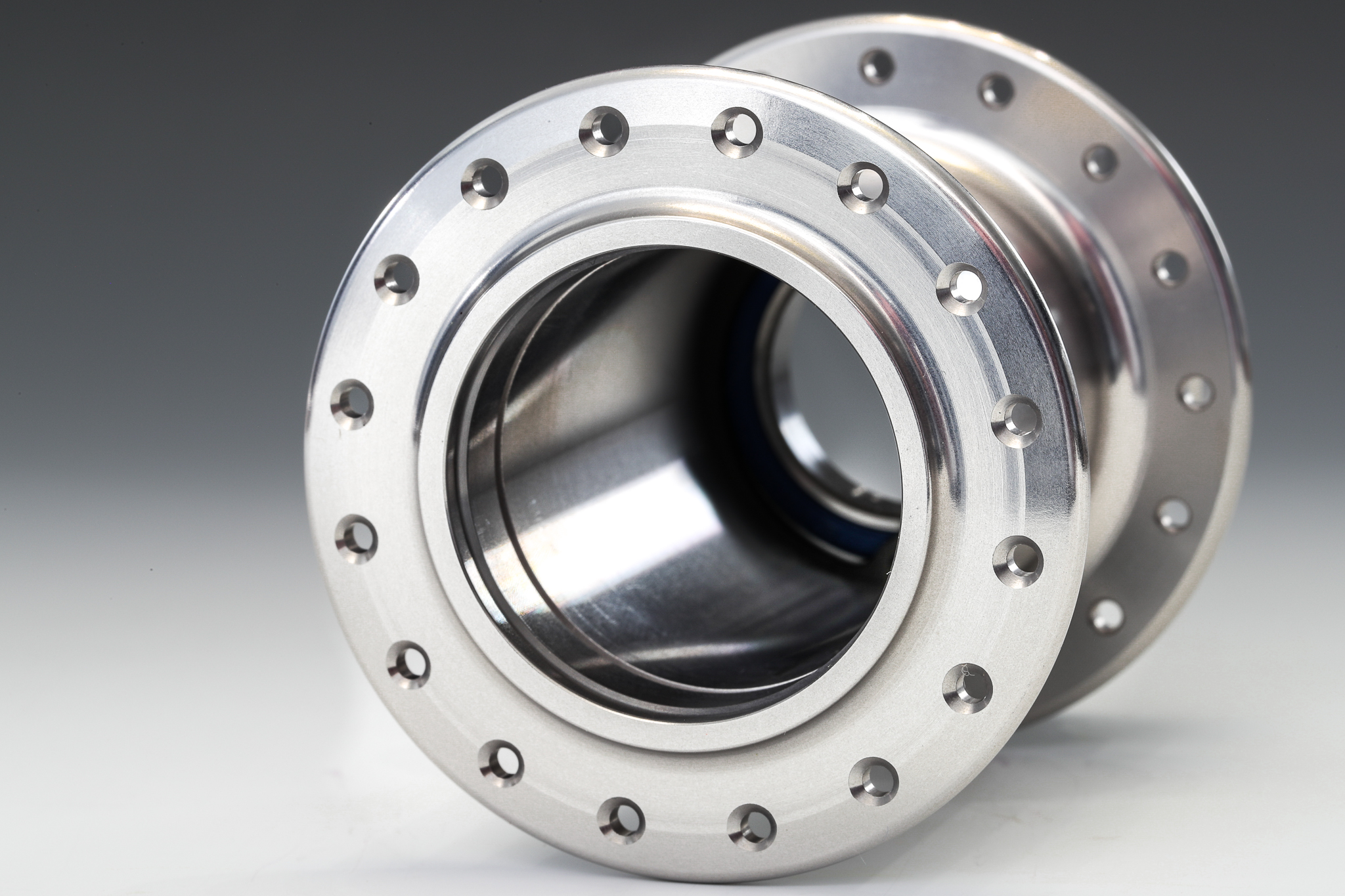

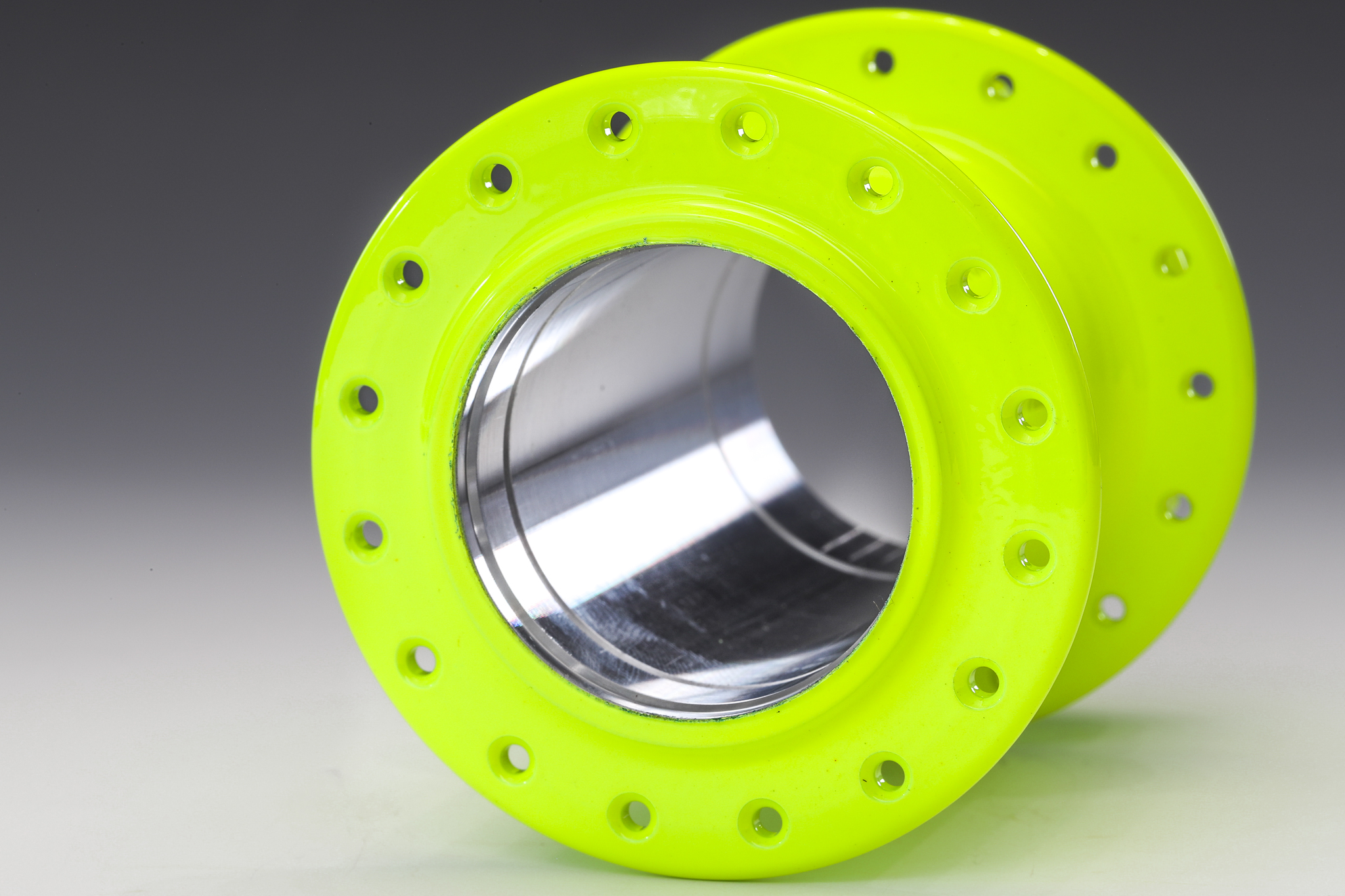

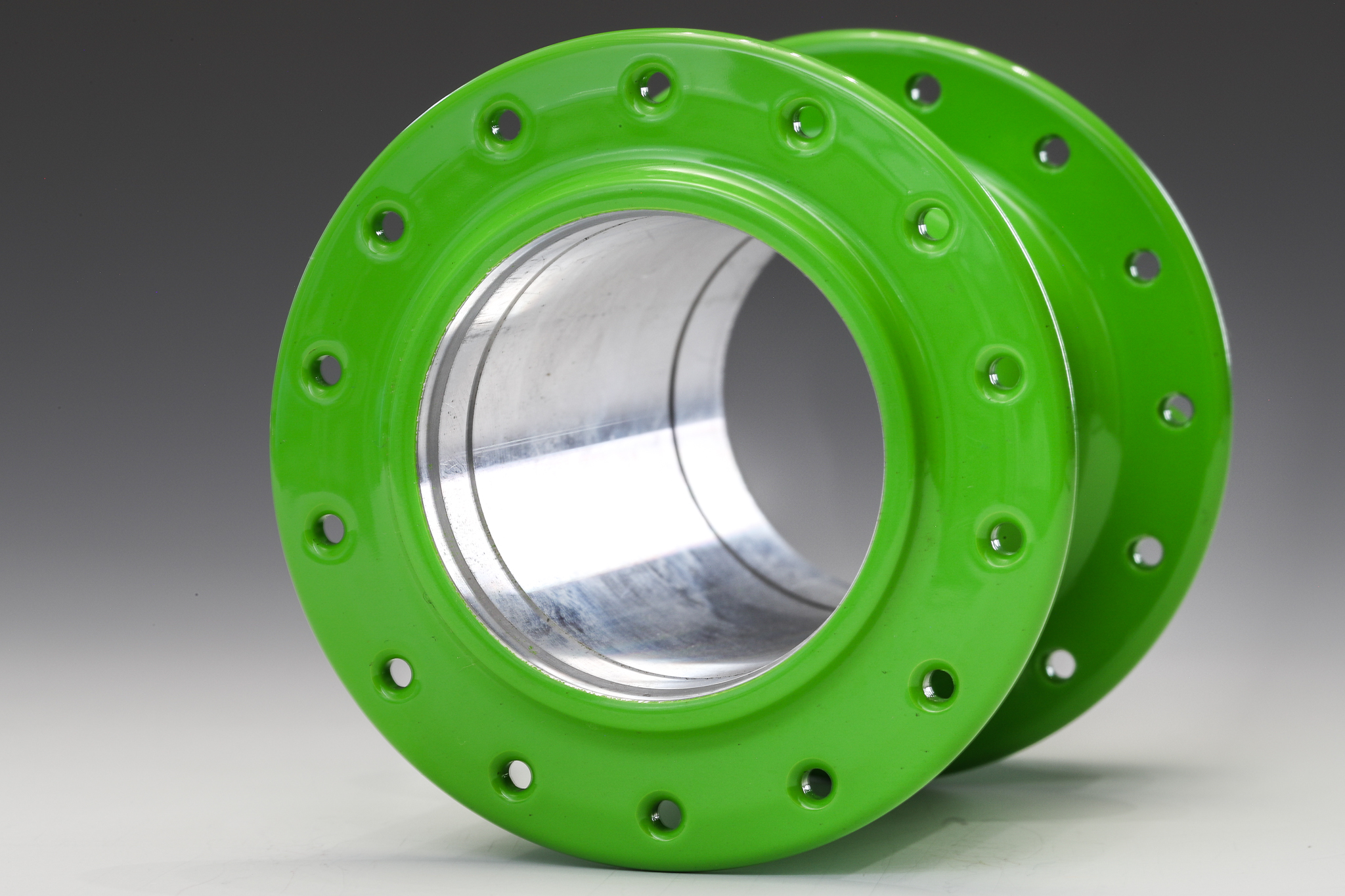

ONYX RACING (Classic Hub)

ONYX RACING Fat Bike hubs are a MADE IN USA product, designed and manufactured in Minnesota, and has been RideFATbike.ca’s “go-to” hub in 2021-22 for all our premium custom-built Fat Bike wheelsets.

Class-Leading efficiency :

0-degree, near-instant engagement

Hybrid-Ceramic bearings for smooth-rolling

Completely silent rolling w/ the Sprag clutch mechanism

-50C to 120C operational range, right out of the box

optional custom laser etching on hub body

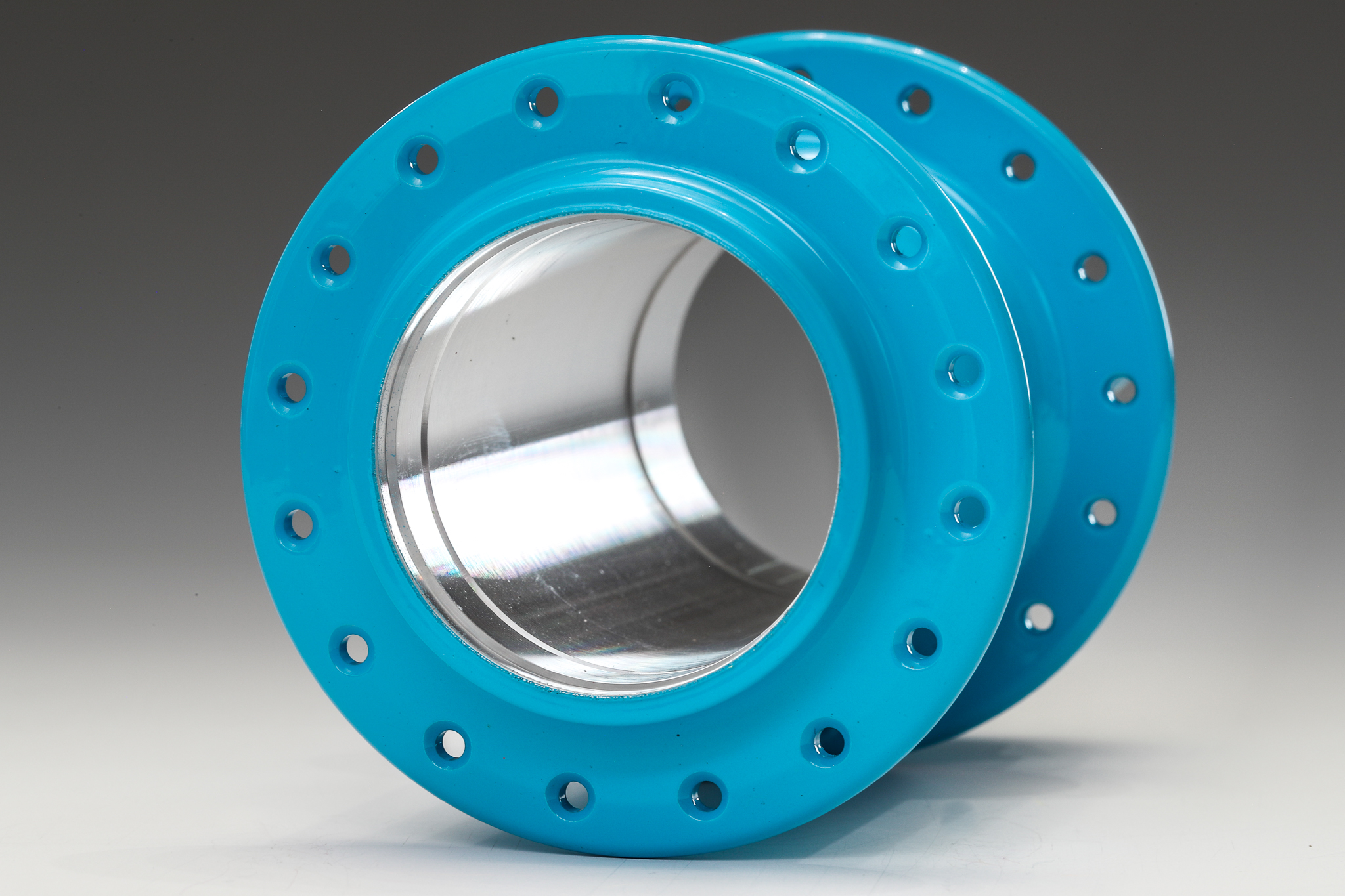

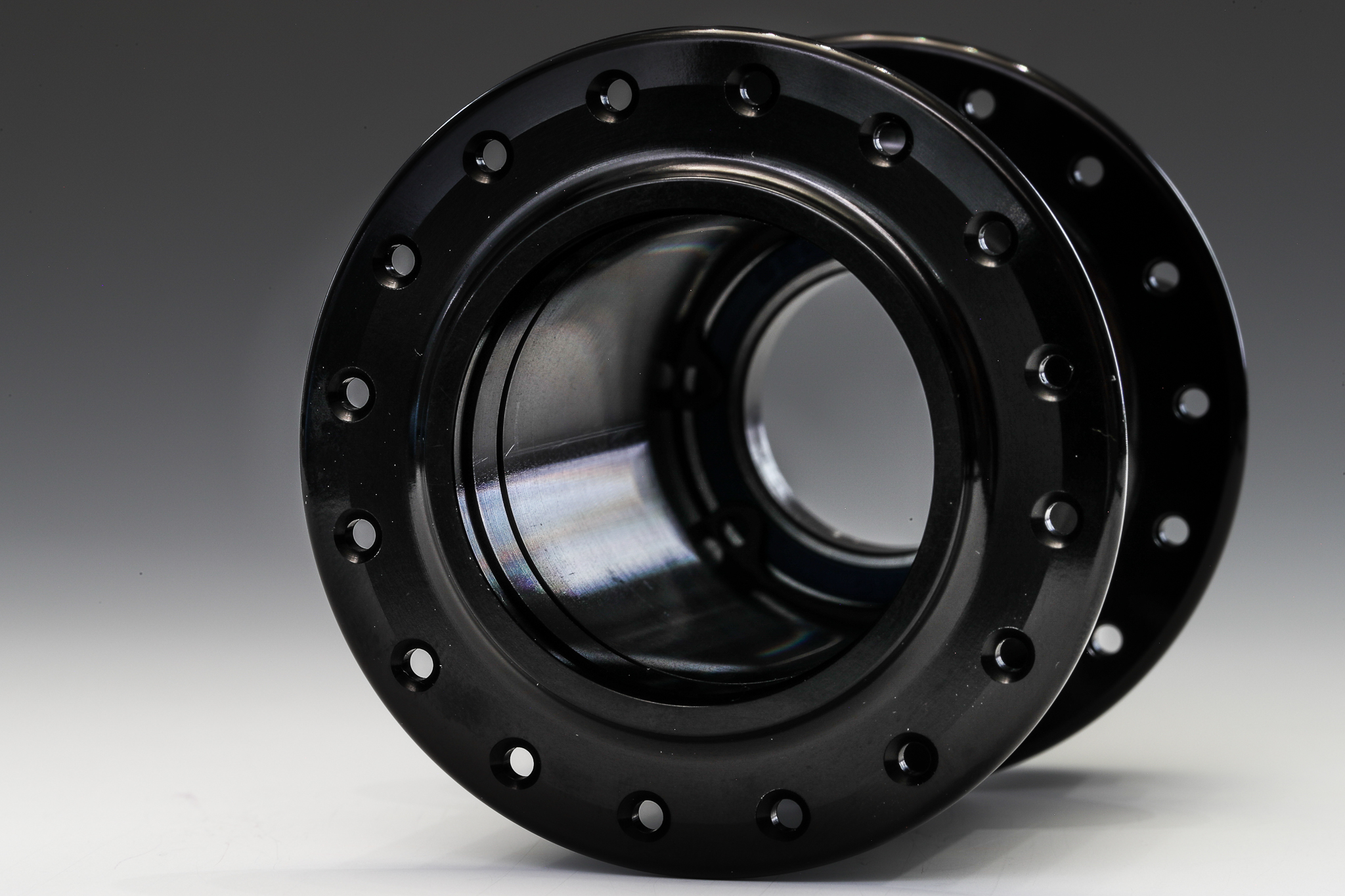

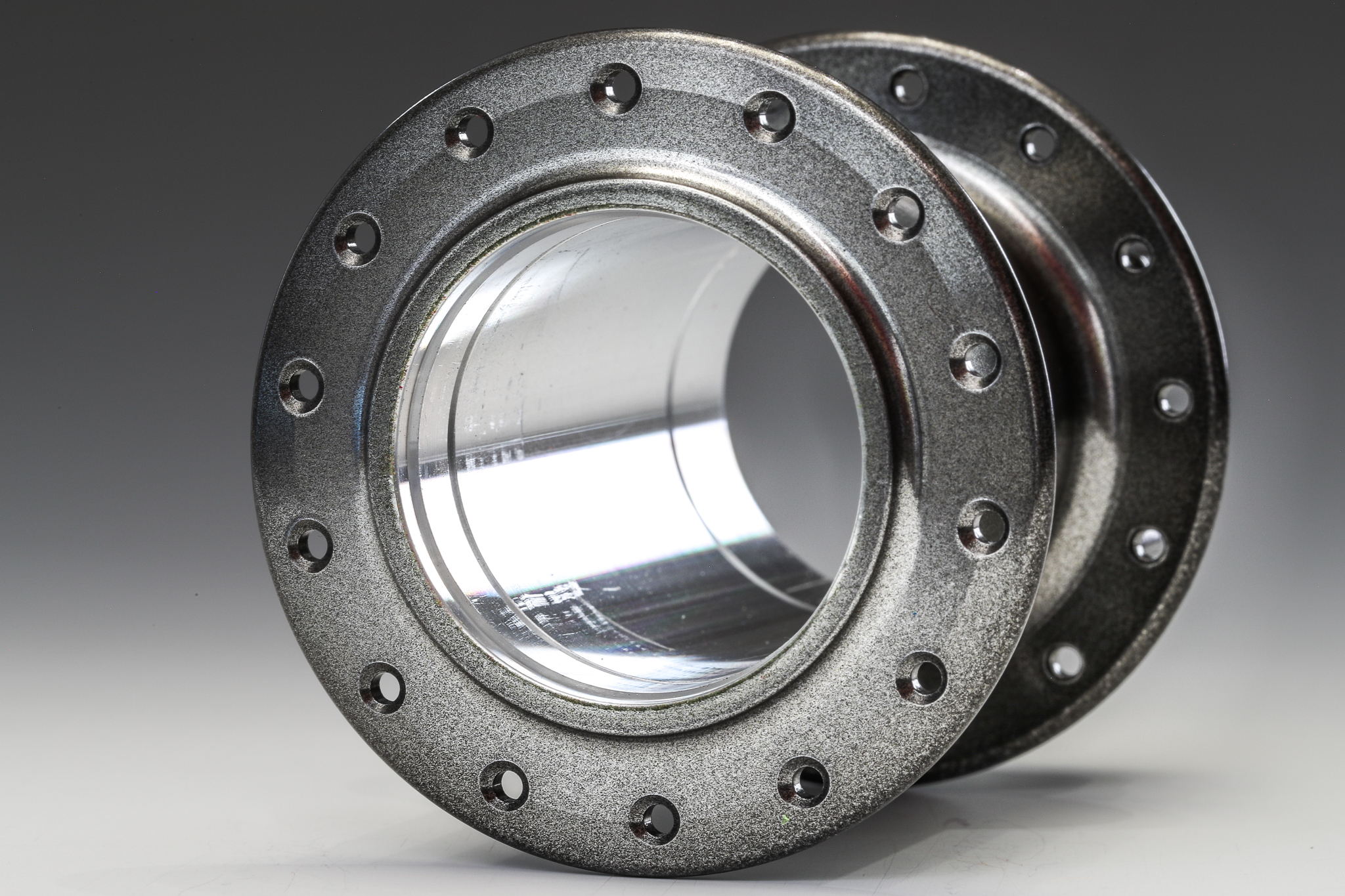

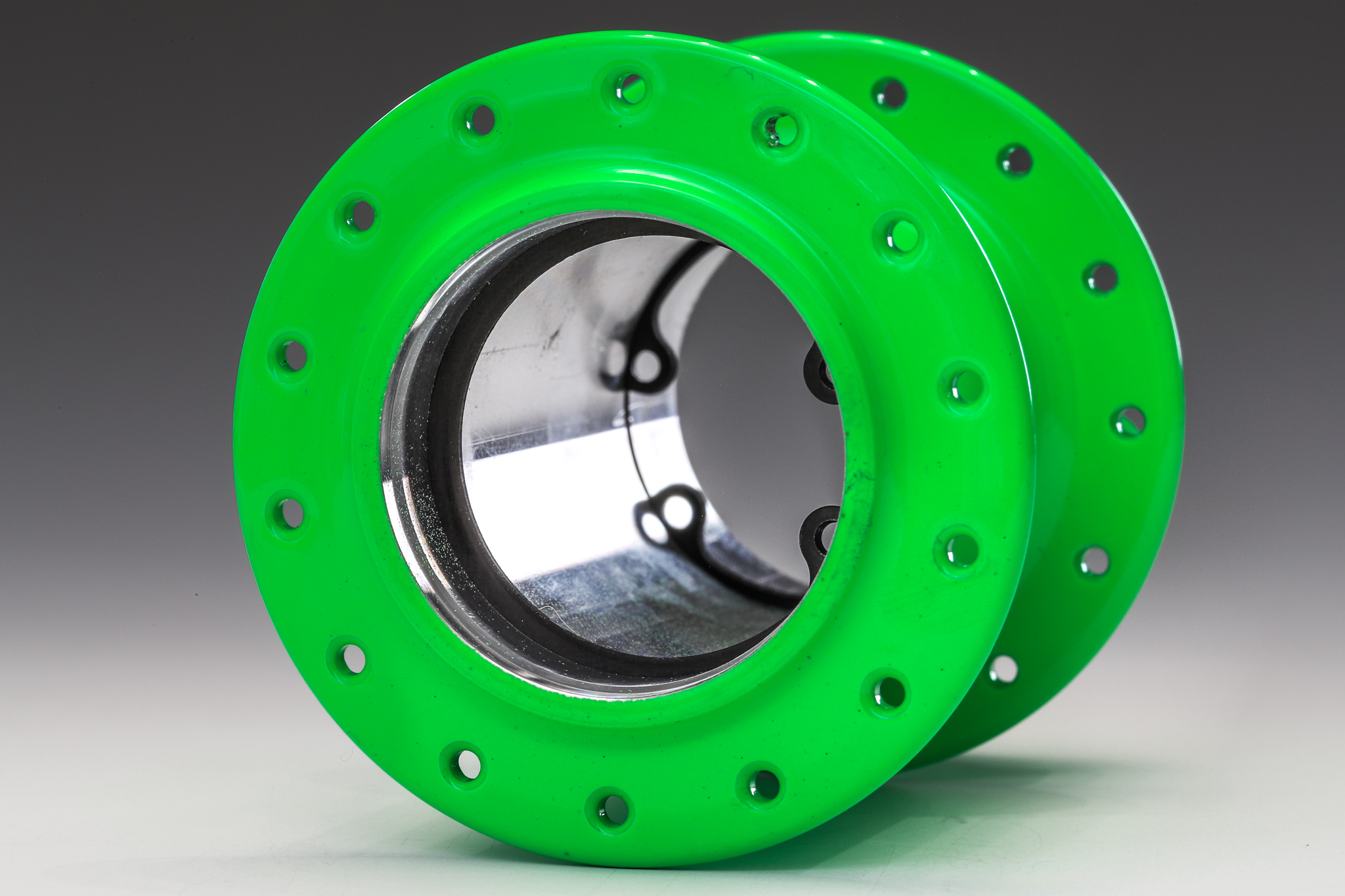

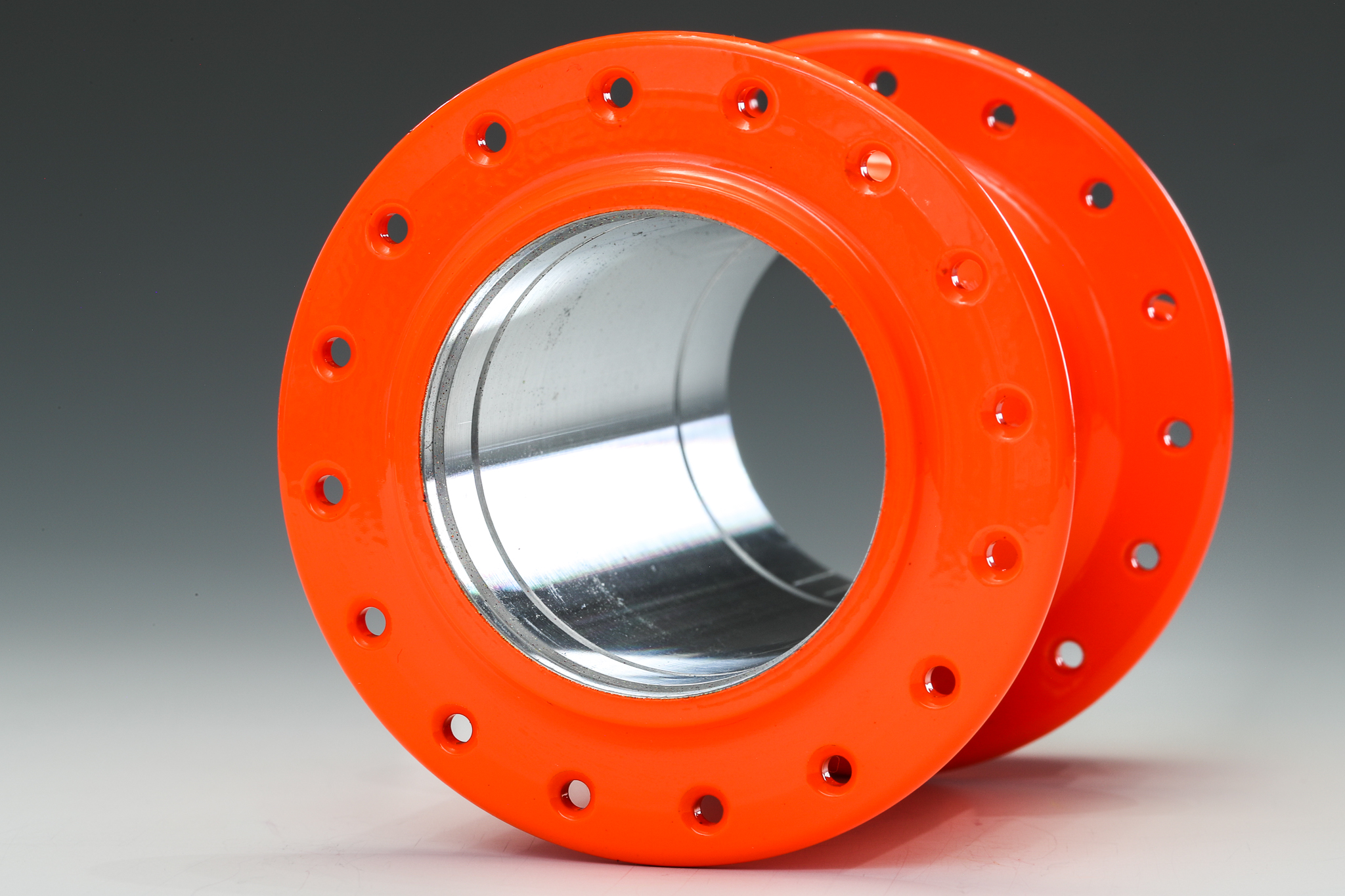

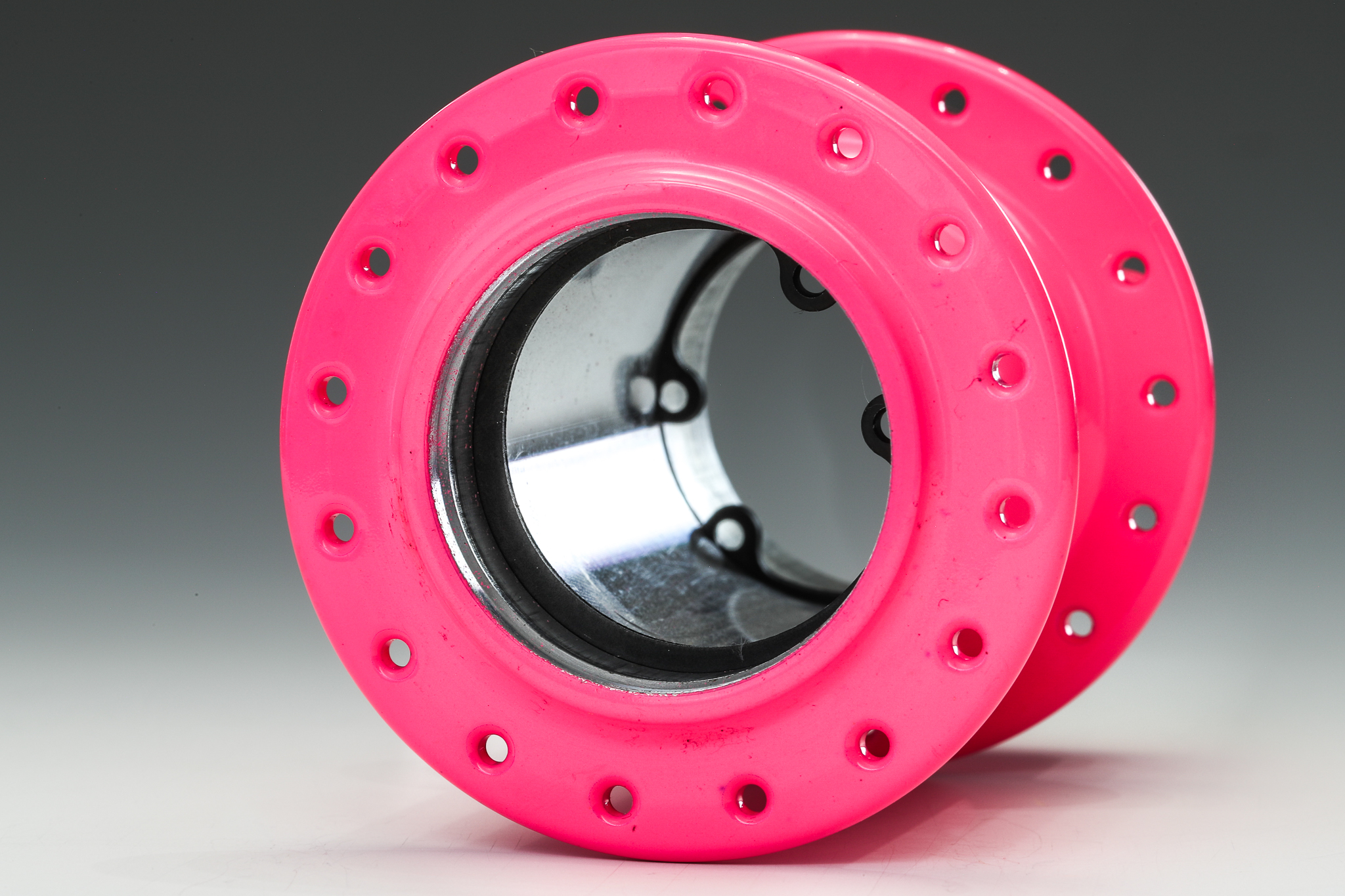

optional (500+) custom anodized or powder coat paint colours to choose from (at an additional cost)

Get into the backcountry and immerse yourself in the wild. Onyx’s patented Sprag clutch helps you confidently traverse the terrain by transferring just the right amount of power to your wheels instantly. Silently roll whether you’re pedaling or not. Experience the outdoors like a bird – quickly and quietly.

And don’t worry about your Onyx hubs in the heat of summer or when slammed with muddy water along the trail. Onyx hubs don’t use oil – the factory grease will last indefinitely for most riders.

Front Hub : 150x15mm (Thru-Axle)

Rear Hub : 177x12mm or 197x12mm (Thru-axle)

Driver : SRAM XD or Shimano hardened stainless steel driver

Engagement : Sprag one-way clutch engagement under load, near instant disengagement when coasting, w/ fully silent operation.

Bearings : Ceramic hybrid, w/ adjustable preload

Drilling : 32 hole, ISO 6-bolt and Centerlock rotor compatibility

Weight (approx) : FR 278gr, RR 538gr (SRAM) = Hubset 816gr (avg)

7075 Aluminum alloy hub shell, w/ titanium bolts

Made in USA, Patented Sprag clutch mechanism

Grease temperature range : -58°F (-50°C) to 248°F (120°C)

Colours : Available in 14 different anodized and 8 different powder coat hub colourways, including custom logo laser etching service.

Warranty : 5 yrs hub, 1 yr Sprag clutch

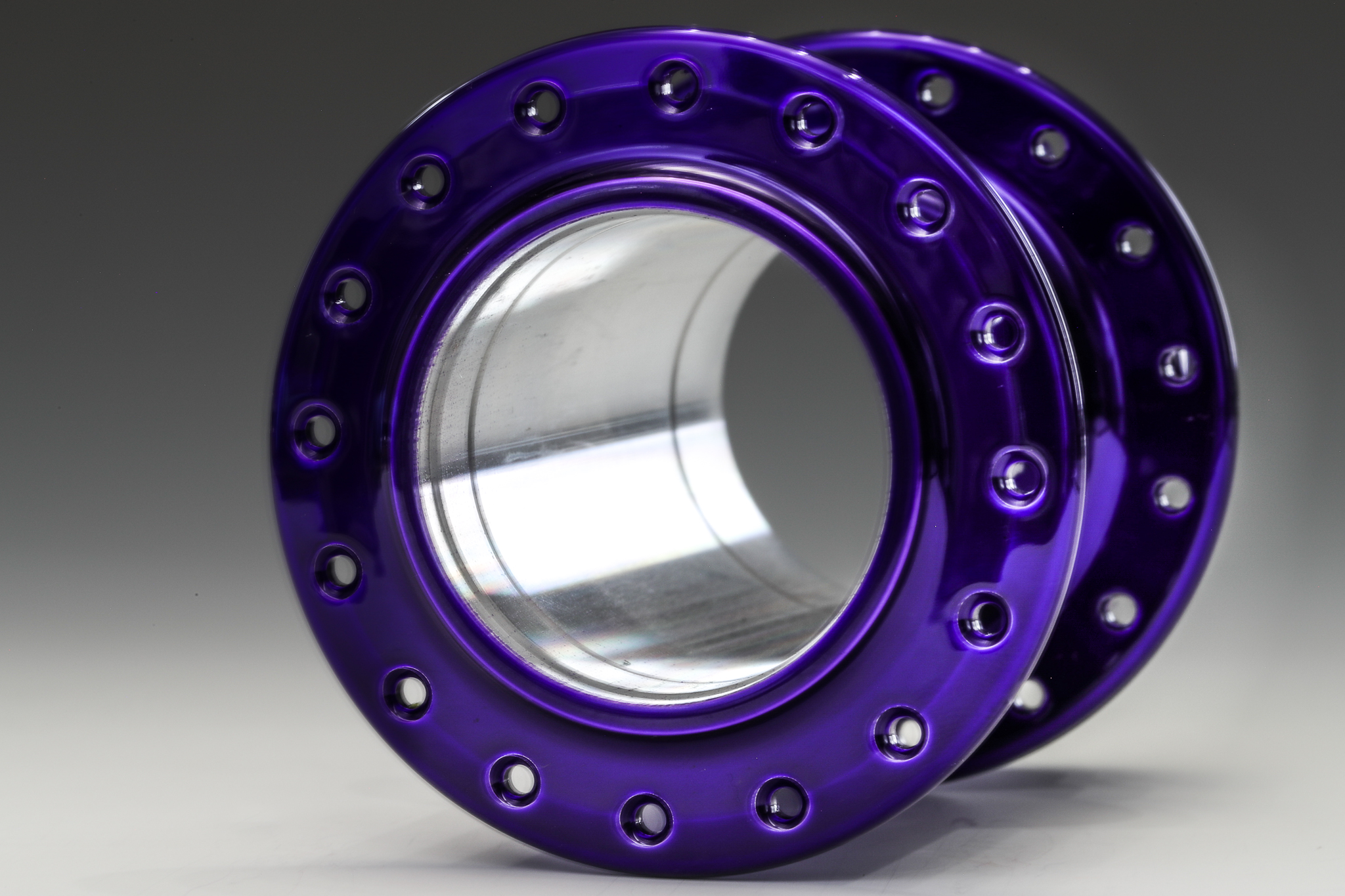

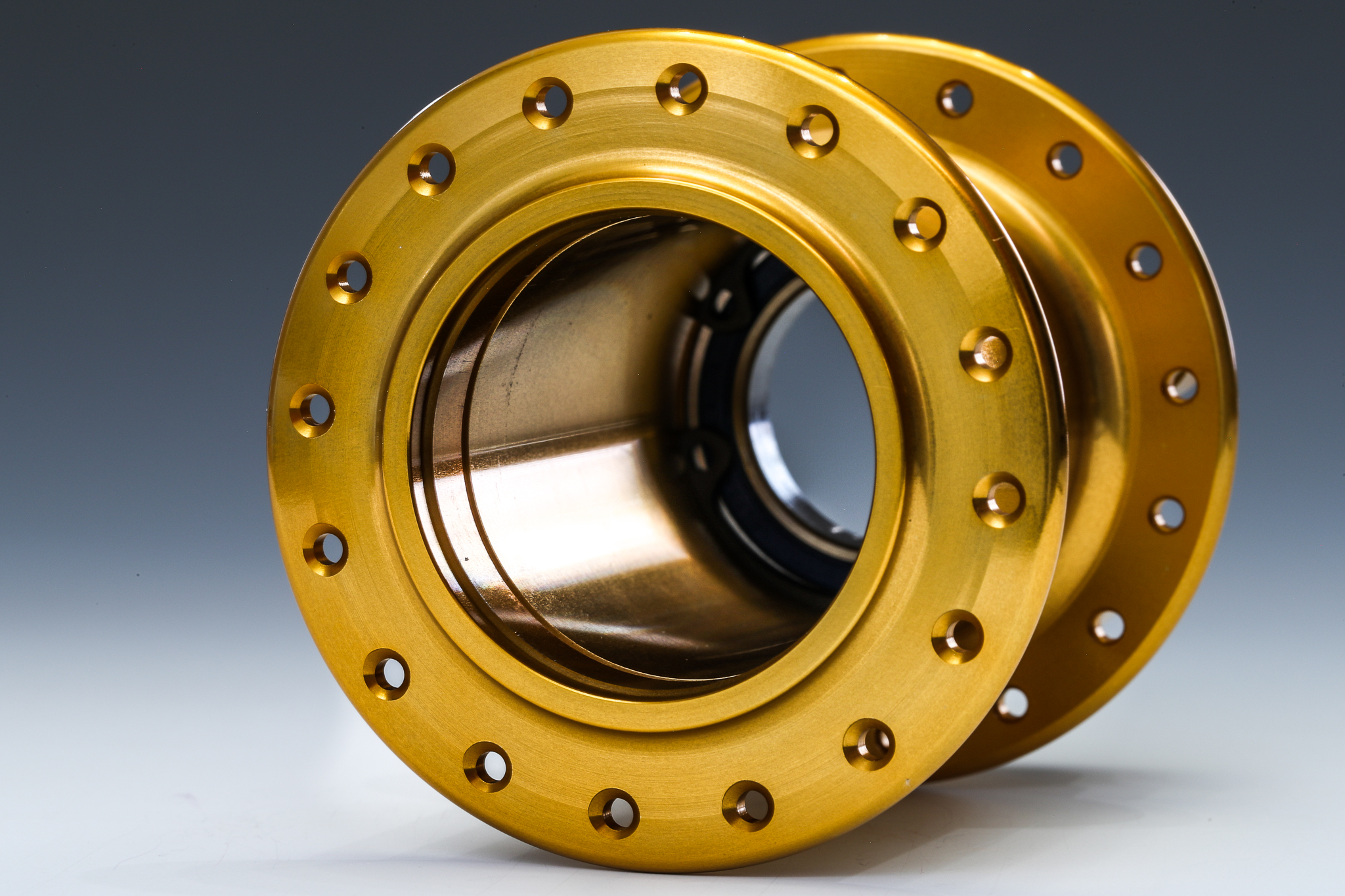

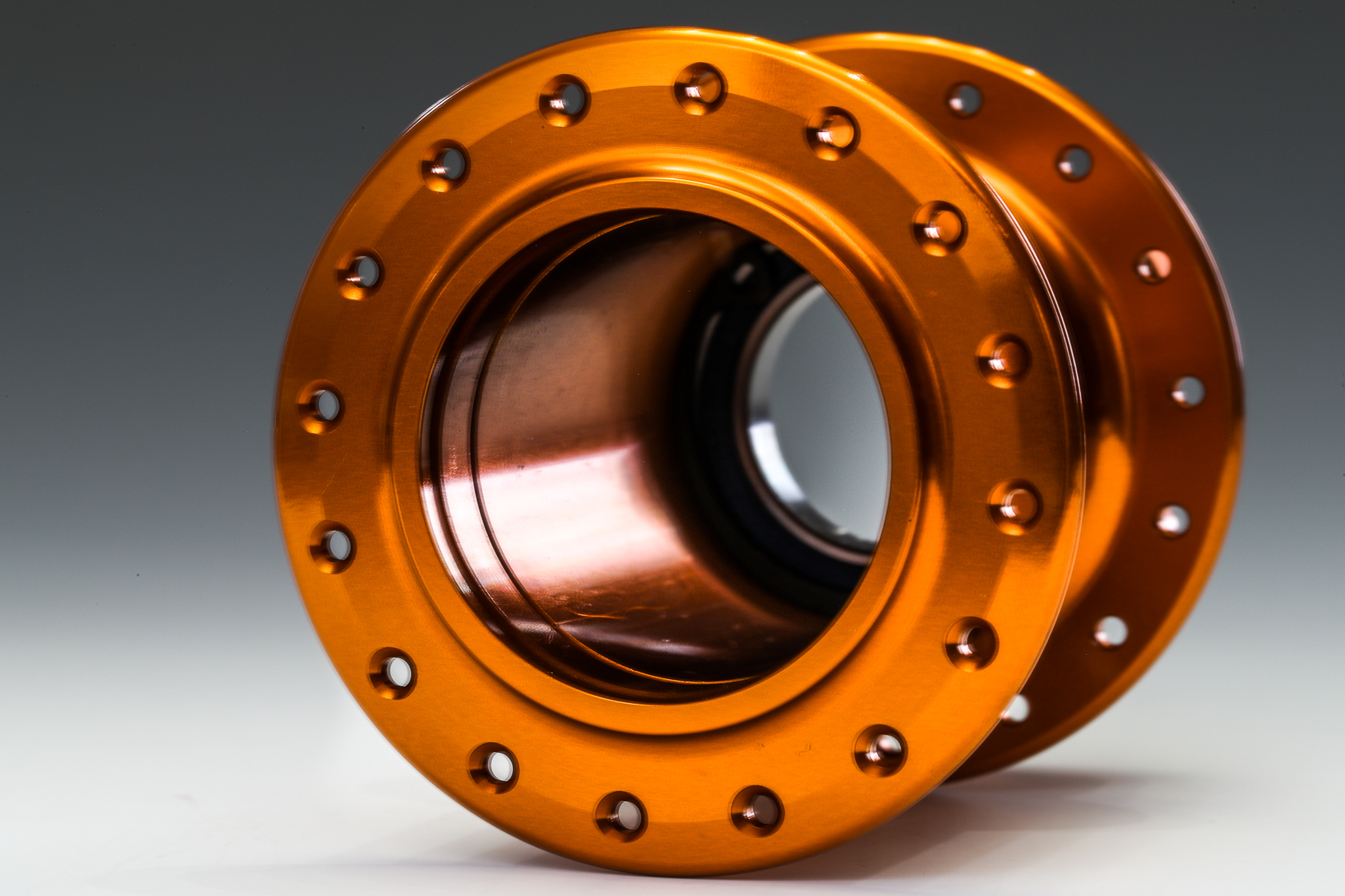

INDUSTRY NINE HYDRA

HYDRA FAT BIKE HUBS MANUFACTURED in 2022 only between NOV and DEC. ** SEASONAL ITEM **

INDUSTRY NINE is a MADE IN THE USA brand, located in Ashville, North Carolina.

Their Hydra Classic hubs are designed for off-road punishment in messy environments. Hydra Classic hubs feature large diameter conventional flanges to improve wheel stiffness and allow the use of standard j-bend spokes.

All Hydra hub versions feature an oversize butted 20/17mm axle, and a heavy duty gearbox with a 690 points of engagement for quick power transfer.

Pawl sound can be increased or decreased, by altering the amount of the special grease used in the 6-pawl housings.

Front Hub : 150x15mm (Thru-Axle)

Rear Hub : 177x12mm or 197x12mm (Thru-axle)

Driver : SRAM XD or Shimano Free hub body

Engagement : 6 pawl freehub, 0.52 degree engagement, 115 pt, 6-phase drive-ring, with 690 total POE.

Engagement : 6 pawl freehub, 115t initial (POE) w/ six-phase pawls, providing a final ratio of 0.52 degrees of 690 (POE) engagement.

Bearings : Enduro steel

Drilling : 32 hole, ISO 6-bolt and Centerlock rotor compatibility

Weight (approx) : FR 200g, RR 347g = Hubset 547gr (avg)

Colours: Available in 11 standard anodized colours

Warranty : 2 yrs, Made in USA

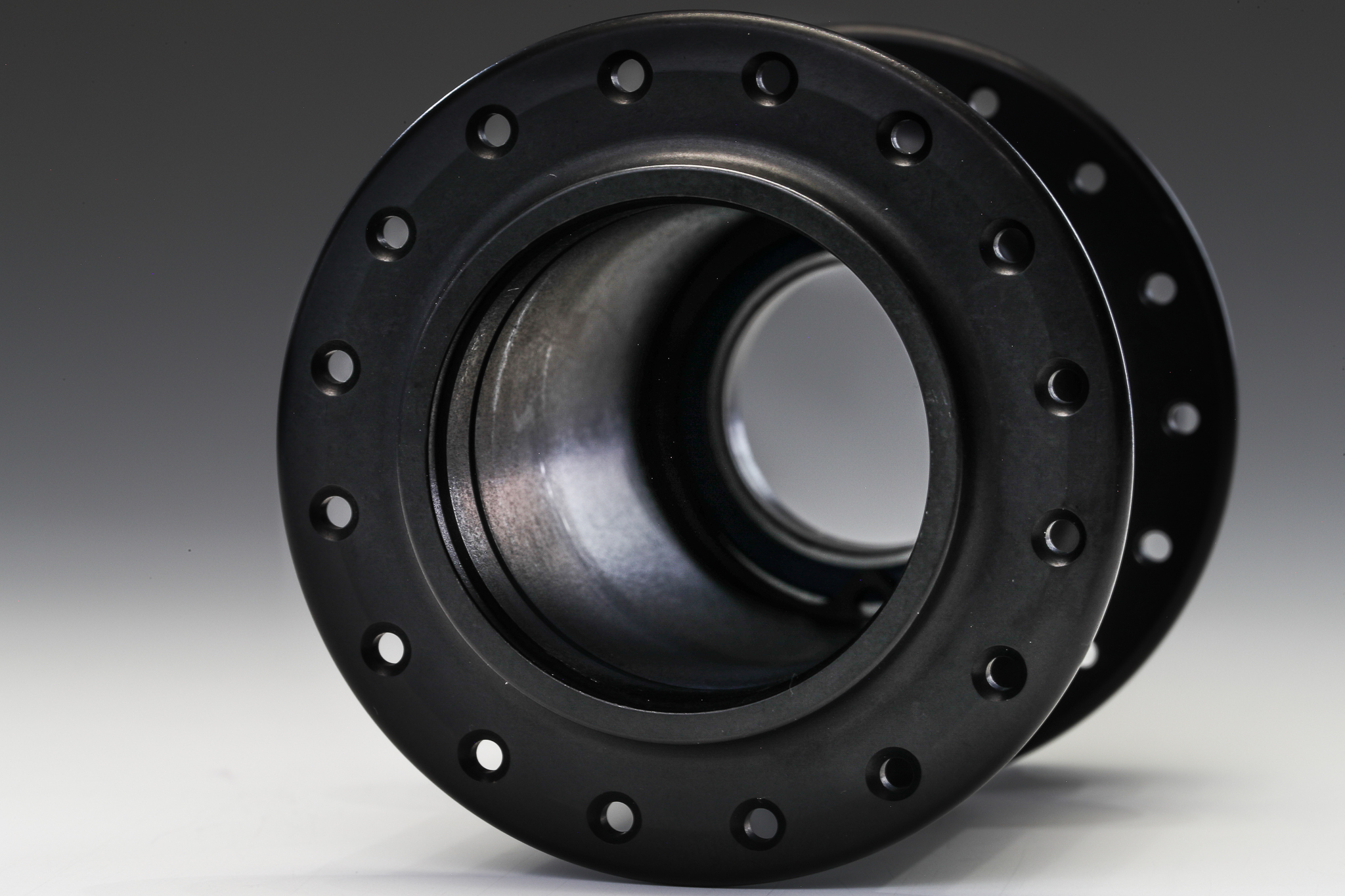

FATBACK AE

“ALASKA EDITION”

According to MFG, the Fatback AE hubs are OEM Novatec “B” series Fat bike hubs made in Taiwan, assembled w/ Japanese EZO steel bearings and repacked with SKF LGLT/2 low-temp grease.

Data provided for reference only.

Front Hub : 150x15mm (Thru-Axle) (Novatec OEM)

Rear Hub : 197x12mm (Thru-Axle) (Novatec OEM)

Driver : SRAM XD or Shimano Free hub body

Engagement : 6 pawl freehub, 72t (POE) single-phase pawls, providing total of 5.0 degrees of engagement.

Bearings : Japanese EZO steel

Cold Weather Rated? : yes, SKF grease is rated to -40C

Drilling : 32 hole, ISO 6-bolt rotor compatibility

Weight (approx) : Hubset = 712gr

Colours : Black only (as of 2022)

Warranty : 2 yrs (as of 2022)

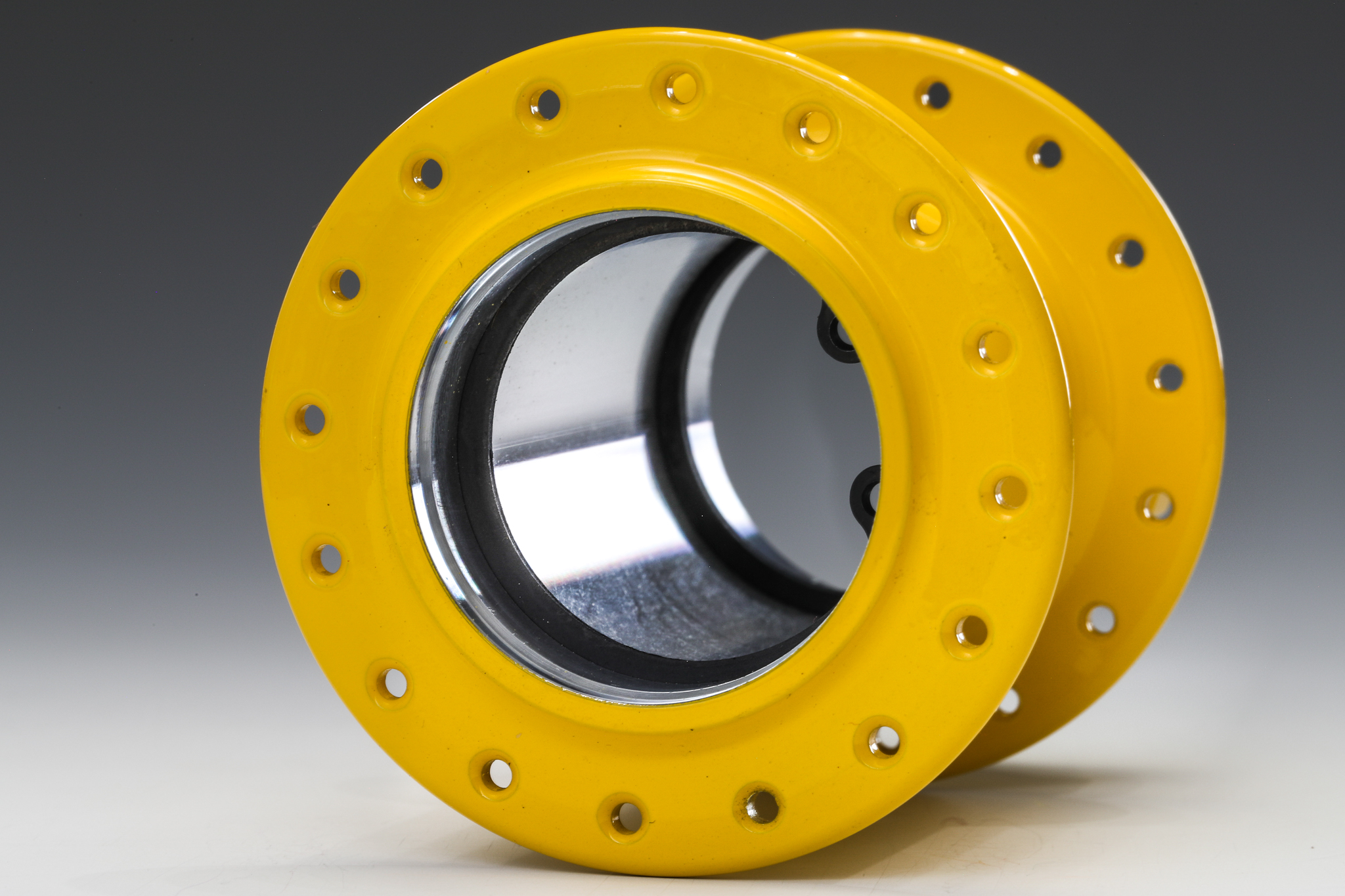

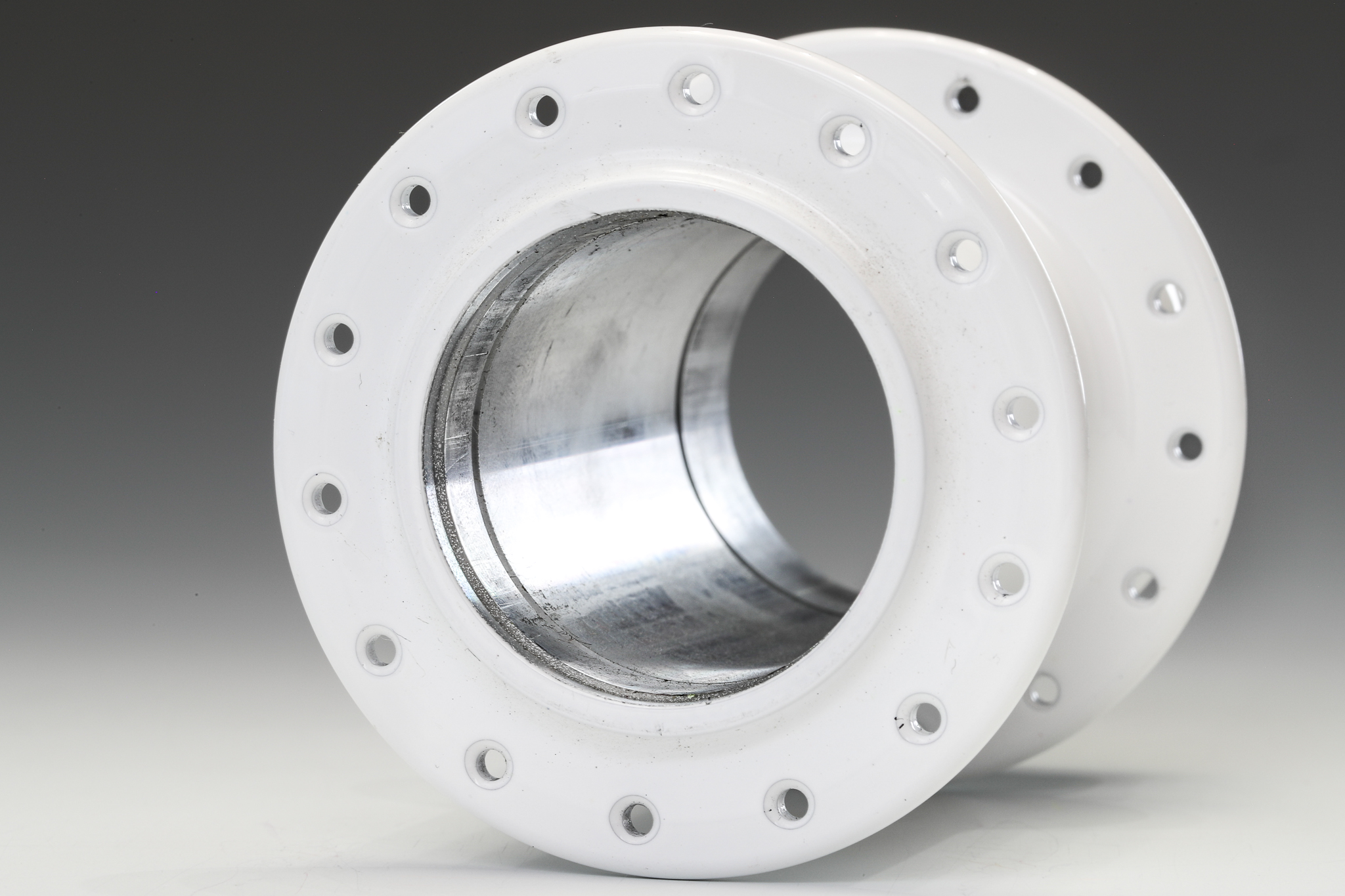

DT SWISS 350 BIG RIDE

Lightweight Fat Bike hubs.

Good cold-weather performance.

Upgrading from the stock 18T ratchet, to the 32T or 54T ratchets, is highly advisable, to reduce the engagement ratio from 20 degrees, down to 10 or 6.7 degrees.

Note : The 18T ratchet is mostly quiet, and increases in sound as you upgrade to either the 36T or 54T ratchet.

Front Hub : 150x15mm (Thru-Axle)

Rear Hub : 197x12mm (Thru-axle)

Driver : SRAM XD or Shimano Free hub body

Engagement : 3 Pawl, Star-Ratchet system (18T : 20 degree, 36T : 10 degree, 54T : 6.7 degree) engagement system

Bearings : Contact-free seal, ABEC 5 bearings

Cold Weather Rated? : YES, to -30C

Drilling : 32 Hole, ISO 6-bolt or Centerlock rotor compatibility

Weight (approx) : ISO 6-bolt > FR 196gr, RR 314gr = Hubset 510gr (avg). Centerlock > FR 175gr, RR293gr = 468gr Hubset

Colours : black and white checker, only.

Warranty : 2 years

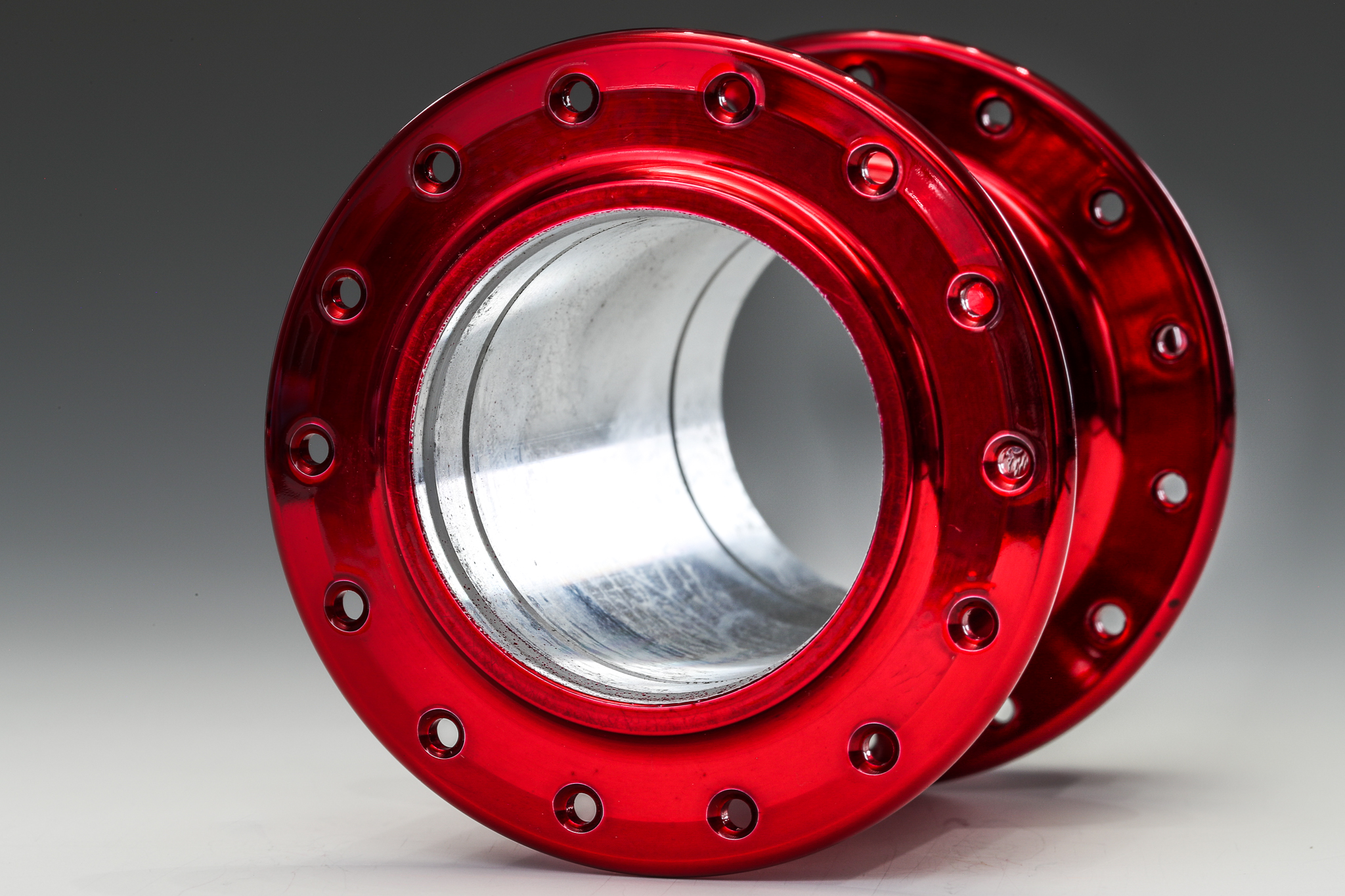

HOPETECH is a quality brand, made in the UK.

According to Hopetech, “The Hope Pro 4 ISO Rear hub features tool free removable end caps for easy conversions between axle sizes. Stainless steel cartridge bearings and large axle diameter keep the Pro 4 rolling smooth.”

“The Pro 4 rear hub is produced from a forged 2014 T6 aluminum billet then CNC machined to final dimensions.”

“The Hope Pro 4 Fatsno ISO Rear hub is available in two shell widths to accommodate 170/177mm and 190/197mm variants. Stainless steel cartridge bearings and large axle diameter keep the Pro 4 Fatsno rolling smooth.”

Note : Hopetech lists the 177x12TA 6-bolt hub at 367g, and the 197x12TA 6-bolt hub at 463g. Both use the same 4 internal bearings.

Front Hub : 150x15mm (Thru-Axle)

Rear Hub : 197x12mm or 177x12 (Thru-axle)

Driver : SRAM XD or Shimano Free hub body

Engagement : 4 Pawl, 44t (POE) engagement, w/ single-phase pawls, providing total of 8.2 degrees of engagement.

Bearings : Sealed stainless Steel cartridge bearings : (2 x 6903, 2 x MR17287)

Drilling : 32 Hole, ISO 6-bolt compatibility

Weight : ISO 6-bolt > FR 255g (15x150TA), RR 367g (177x12TA), RR 463g (12x197TA) = Hubset 718g (avg).

Colours : 6 different Anodized hub colourways offered.

Warranty : 2 years

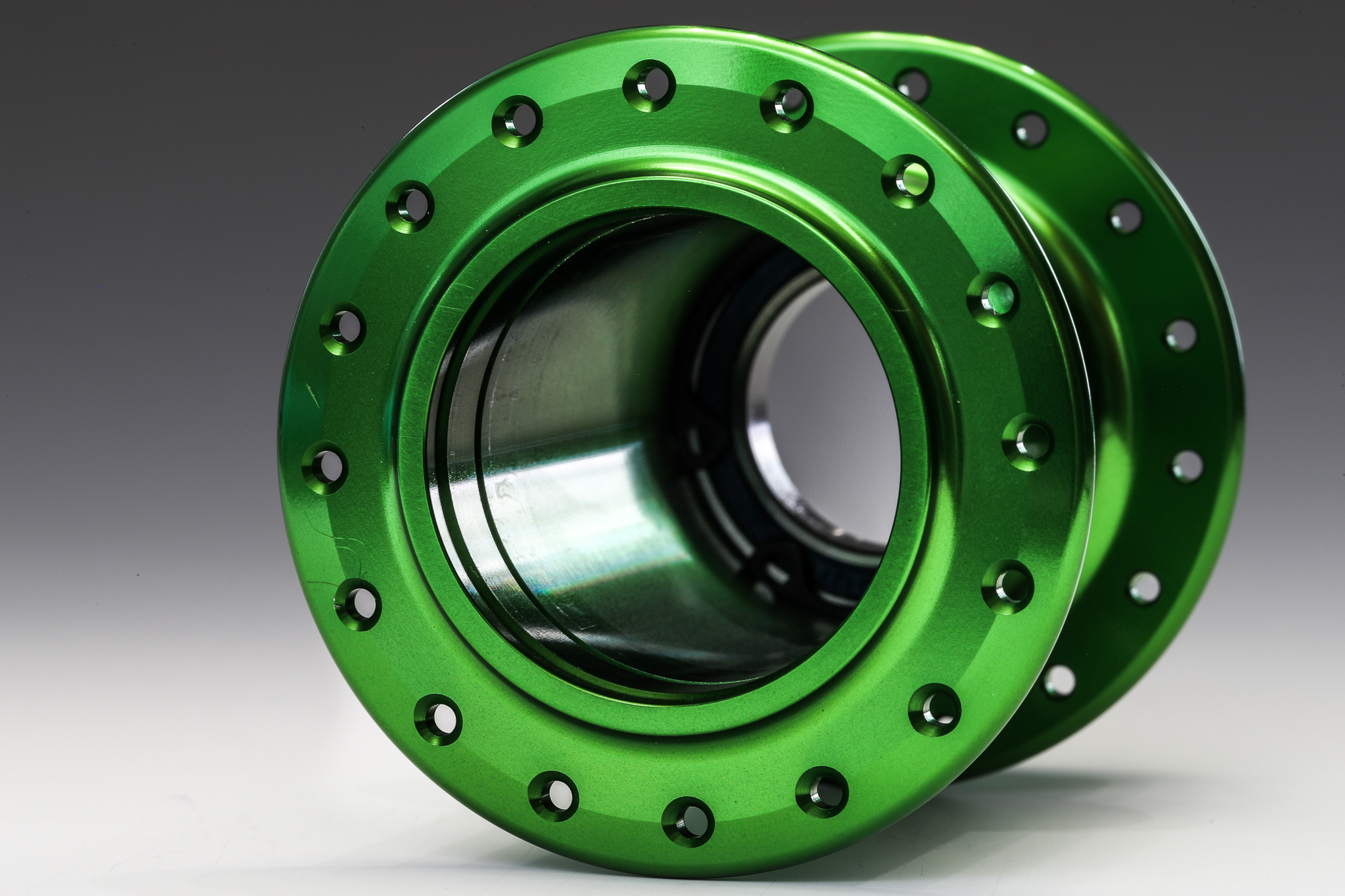

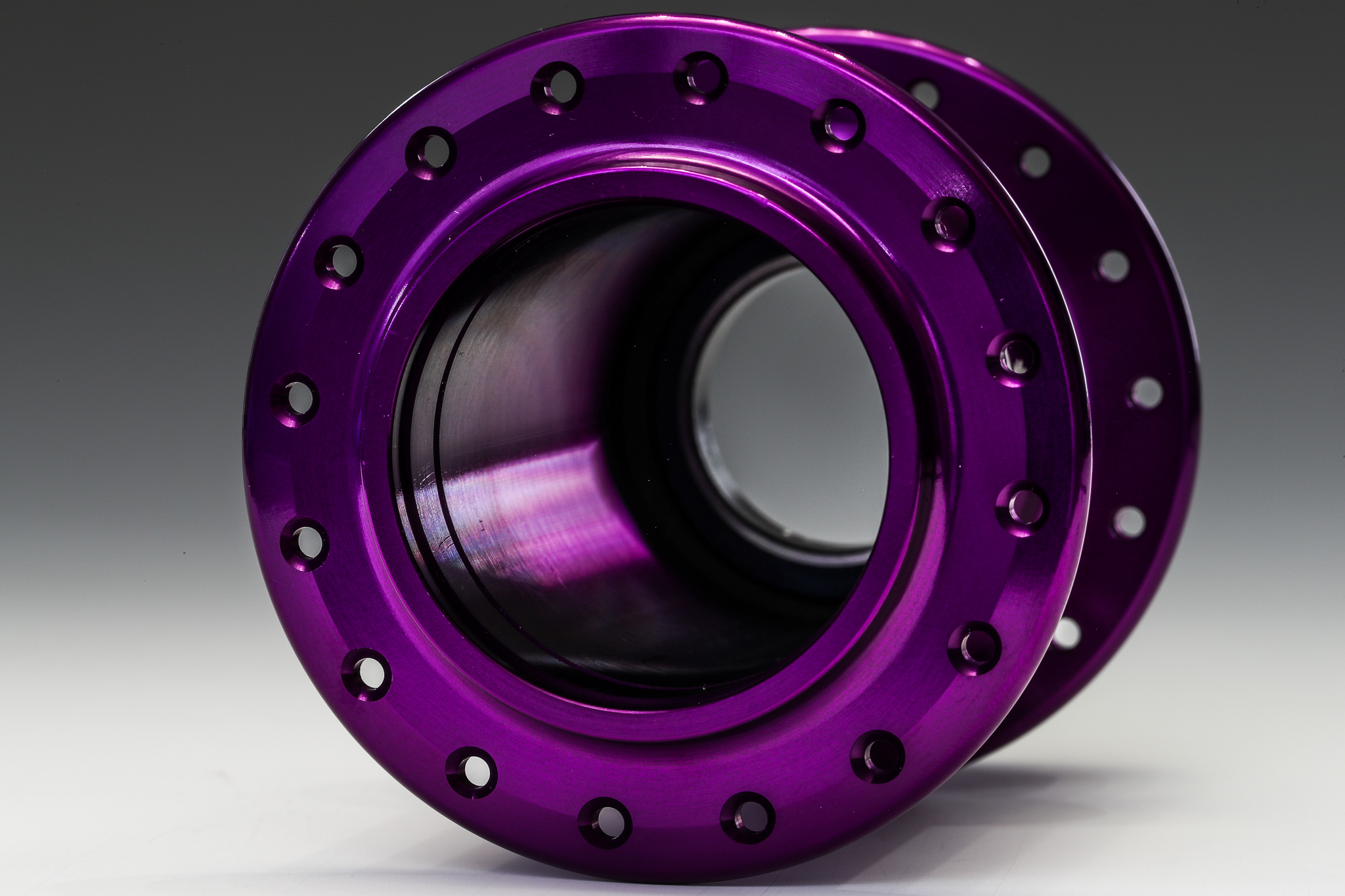

HADLEY RACING offers top of the line, TITANIUM Fat Bike hubs. The rear hub has a precise 4-pawl, 72T, 5 degree engagement.

Hadley does not have a website.

Hadley is a MADE IN USA brand, with all parts CNC machined in Southern California.

Known for its long-standing excellent Industry reputation, Hadley Racing completely lacks a social media presence, or company website. Hadley is one of the best brands in the World, that you may have never heard of!

Front Hub : 150x15mm (Thru-Axle)

Rear Hub : 177x12 or 197x12mm (Thru-Axle)

Driver : SRAM XD or Shimano Free hub body

Engagement : 4 pawl freehub, 72t (POE) single-phase pawls, providing total of 5.0 degrees of engagement.

Material : CNC’d Titanium

Bearings : ABEC-5 Steel

Drilling : 32 hole, ISO 6-bolt rotor compatibility

Weight (approx) : Hubset = 618gr

Colours : Anodized Black only

Warranty : 5 years